Sheet Metal parts made from Galvanized steel & sheet metal parts with zinc plating

For sheet metal parts, steel is a popular choice for its strength, durability, and economy. However, steel is prone to rust and corrosion over time. This is where anti-corrosion coatings such as Pre-galvanized and zinc palting come into play. But which is the better choice: Sheet metal made from steel and then Zinc plating after fabrication or sheet metal made directly from Pre-galvanized steel?

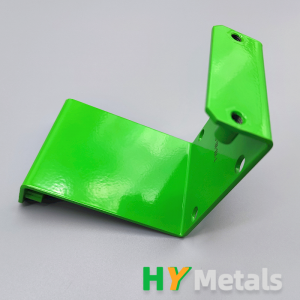

At HY Metals we work on a variety of sheet metal fabrication projects, including many steel projects, every day. For steel, there are two main options: raw steel (CRS) and galvanized pre-galvanized steel. We offer a variety of finish options for steel, including Zinc plating, nickel-plating, chrome-plating, powder-coating and E-coating.

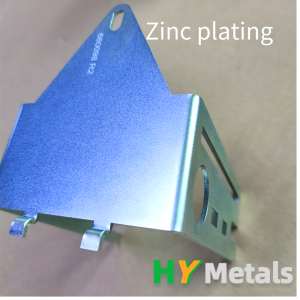

Pre-Galvanized and After-Zinc plating are two of the most popular options for corrosion-resistant coatings for sheet metal parts. Galvanizing involves applying a thin layer of zinc to the surface of steel through a process called electroplating. This creates a barrier between the steel and the environment, preventing rust and corrosion. Zinc plating, on the other hand, involves applying a layer of zinc to the steel after it is formed into a sheet metal part. This provides a more thorough and complete coating, as even the cut edges of the metal are covered.

So, which is the better choice: Zinc plating after fabrication or using Pre-galvanized steel material directly for fabrication? It depends on the specific needs of your project. Pre-Galvanizing is often a lower cost option as it allows for greater flexibility in the manufacturing process. It also provides a better surface finish because plating can be applied more uniformly and precisely. However, this method does not provide a complete coating like Zinc electroplating. If your project requires maximum corrosion protection, Zinc plating after sheet metal fabrication may be a better choice.

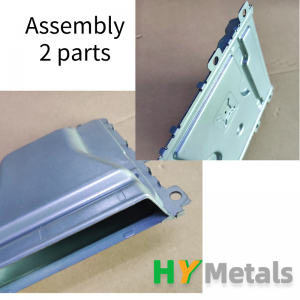

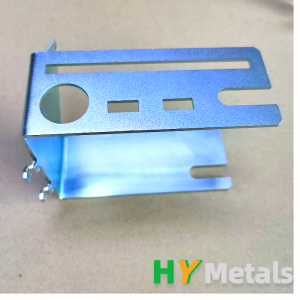

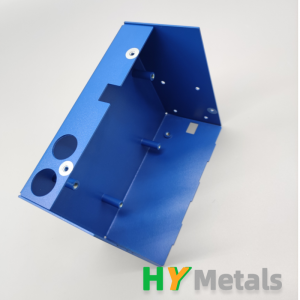

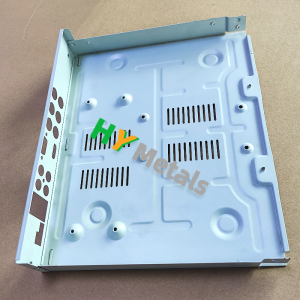

To illustrate the difference, let’s see attached one set of our stamped parts with anti-rust requirements as an example. Because this is a mass production order, the customer need cost effective and same time high quality component that meets corrosion protection requirements. Considering the parts are used inside of a machine, Pre-galvanized steel is enough for the usage even the cut edges of the metal was not coated.

Both galvanized and zinc plating are effective anti-corrosion coatings for steel sheet metal parts. Choosing between the two depends on your specific project needs and priorities, whether it’s cost, surface finish or maximum corrosion protection. At HY Metals, we can help guide you in choosing the best options for your project and provide the proper finish to meet your needs.