Precision Metal Etching Services from HY Metals: Seamless Part Fixing Solutions

Introduce:

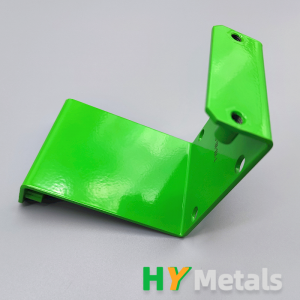

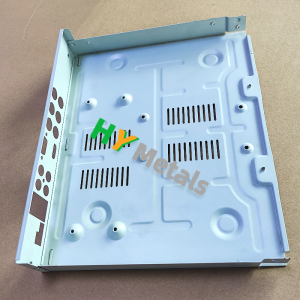

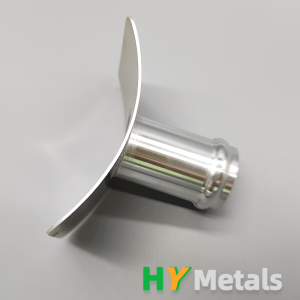

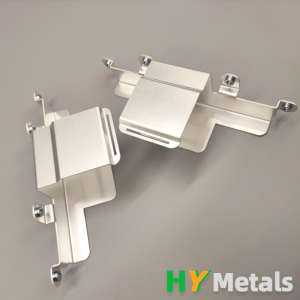

In the world of custom manufacturing, precision etching plays a key role in creating complex and high-quality metal parts. HY Metals, a leading supplier of sheet metal parts and CNC machined parts, has become a premier provider of precision etching services. With a commitment to excellence and a focus on delivering top-notch quality, HY Metals has earned a reputation for producing quality etched products that meet the exacting standards of its diverse customers.

Learn about the etching process:

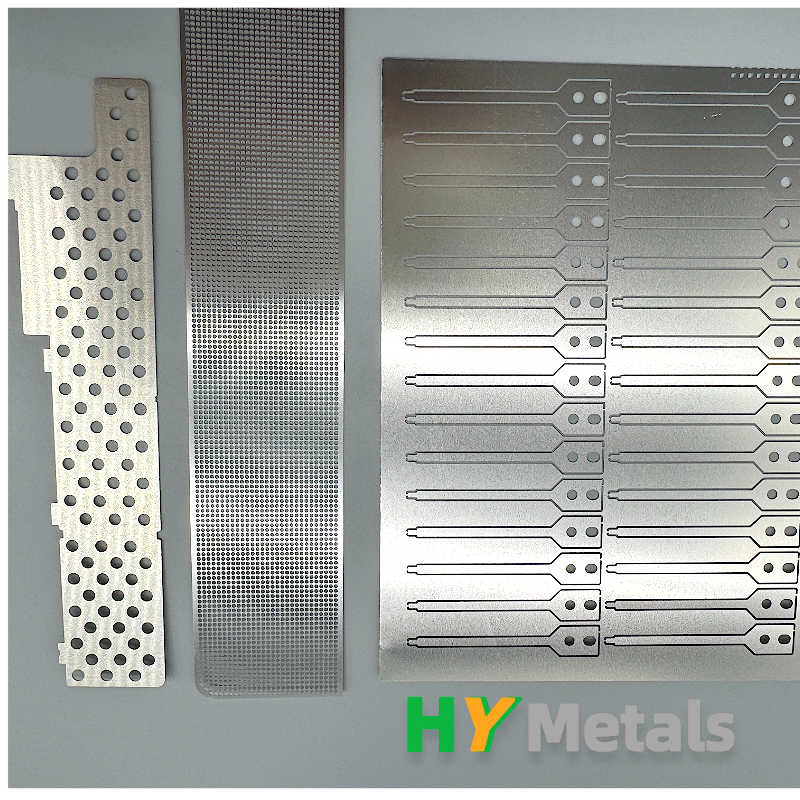

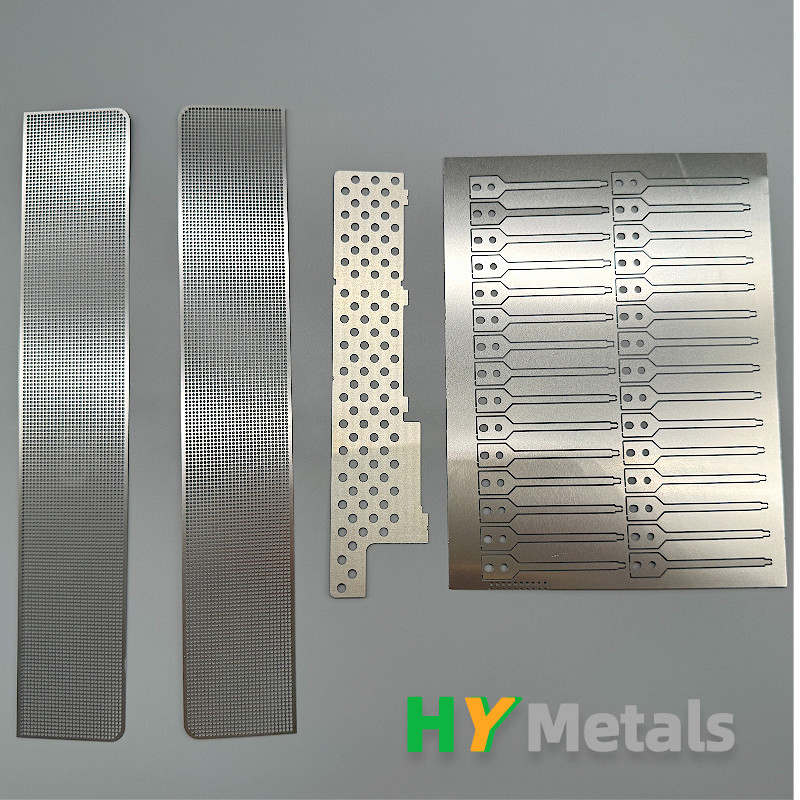

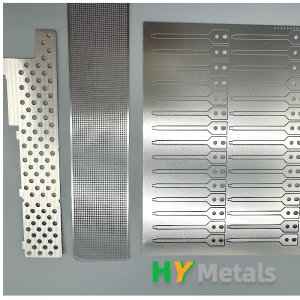

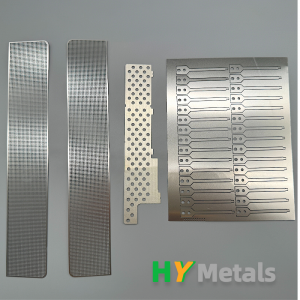

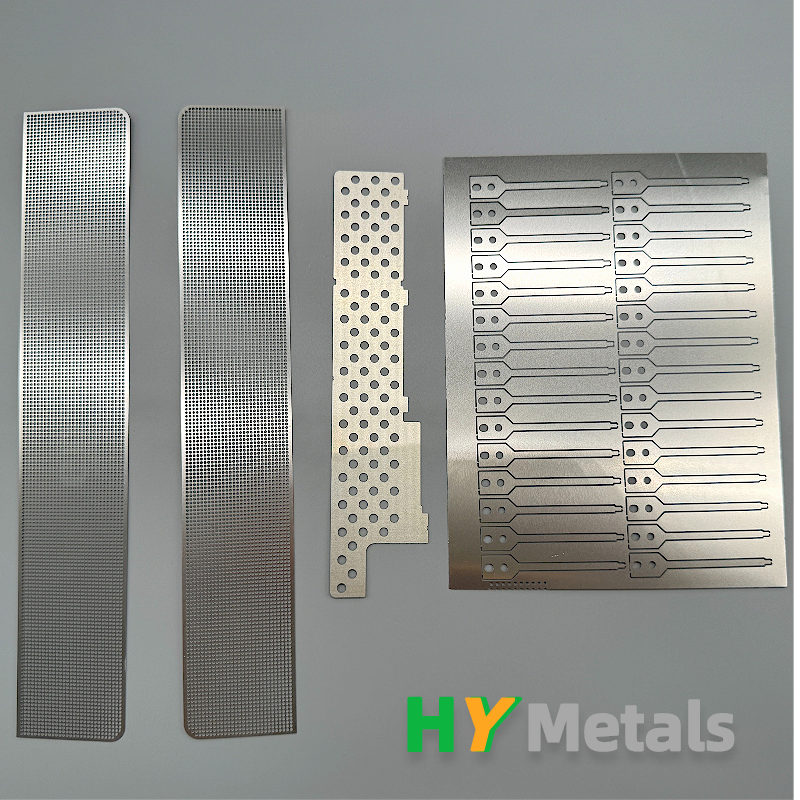

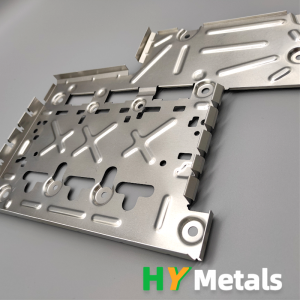

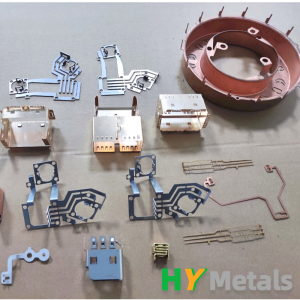

Etching is a versatile and precise metalworking technique that involves the selective removal of material from a metal surface to create complex designs, patterns, or functional features. At HY Metals, the etching process begins with the careful selection of high-quality, thin materials including stainless steel, copper, nickel plate etc. This material is then carefully etched to create a gasket or custom shape with smooth edges and impeccable surface quality. The result is a range of etched products with exceptional precision and durability.

Quality Assurance and Workmanship:

At the core of HY Metals’ etching capabilities is a relentless focus on quality assurance and workmanship. Each etched plate undergoes rigorous inspection to ensure there are no scratches, dents or any defects on the surface of the material. This unwavering commitment to quality is reflected in the seamless surfaces and superior performance of etched products, making them ideal for a wide range of applications across industries.

The Art of Custom Manufacturing:

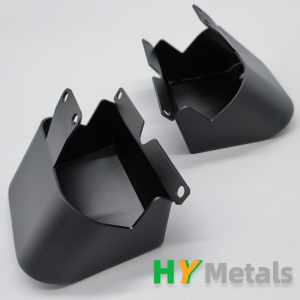

HY Metals prides itself on being a specialist custom manufacturing supplier, adept at meeting our customers’ unique needs. The company’s expertise in etching goes beyond standard product ranges to create custom-designed etched products that meet specific requirements. Whether it’s intricate designs, intricate geometries, or specialty finishes, HY Metals leverages its advanced etching capabilities to bring our customers’ visions to life with precision and skill.

Versatility of Etching Products:

The etching products offered by HY Metals cover a variety of applications due to their superior quality and precision. From decorative components in architectural designs to functional components in electronic devices, the versatility of etched products is limitless. Customers can rely on HY Metals to provide etched plates that not only meet their exact specifications, but exceed their expectations in terms of quality and performance.

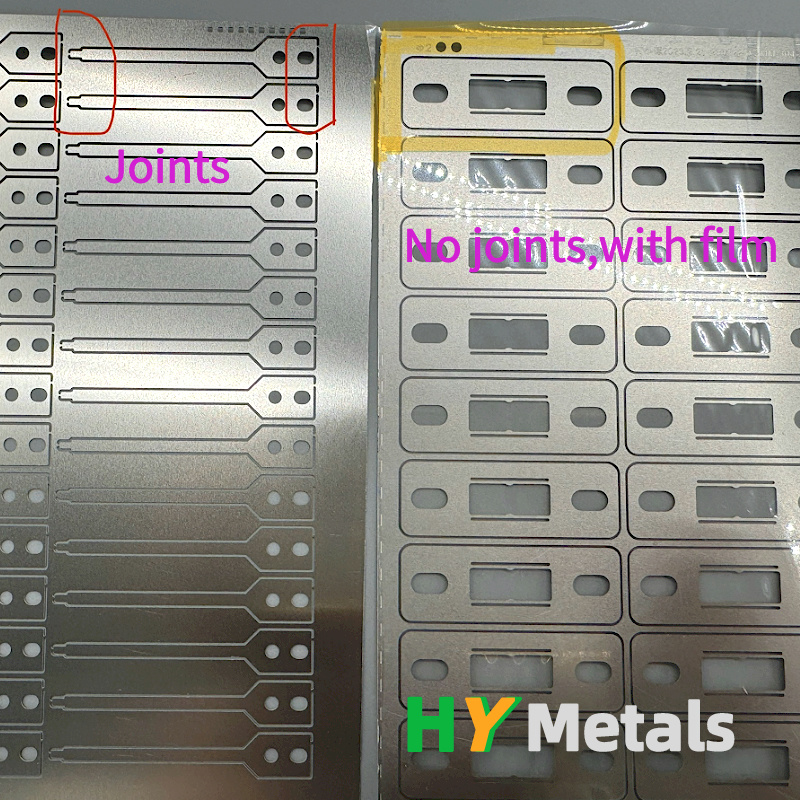

Free junction point etching solution:

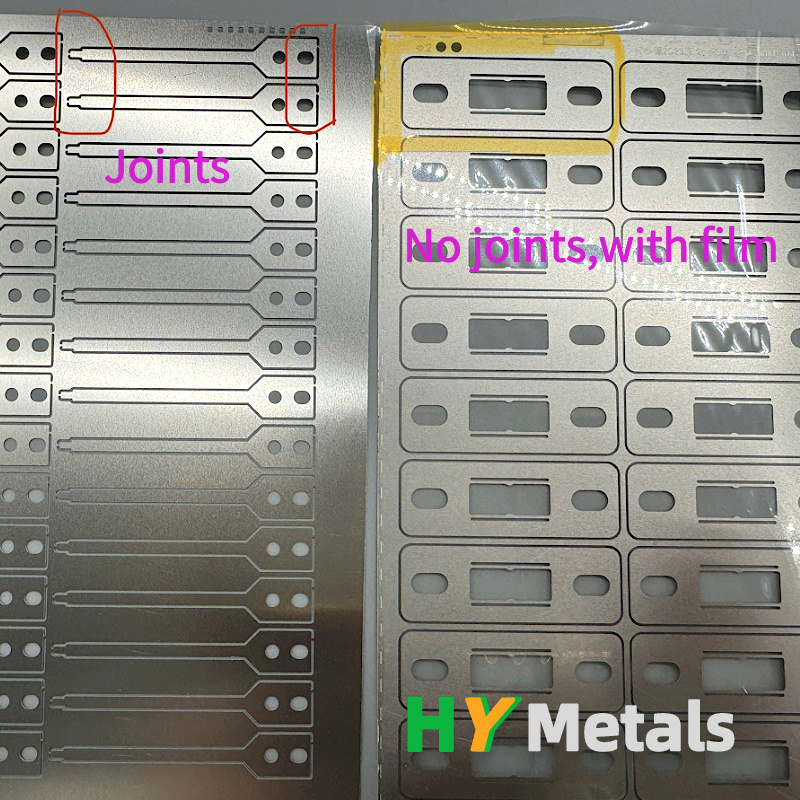

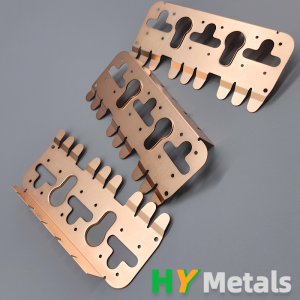

In the world of precision etching, the process of patterning multiple parts on a single sheet and designing joints to retain the parts during etching has long been standard practice. However, this traditional approach poses challenges, especially for critical decorative components that require seamless edges and perfect finishes. HY Metals, a leading custom manufacturing supplier, has introduced a breakthrough solution to solve this problem, revolutionizing the etching process and improving the quality of etched products.

Introducing innovative solutions:

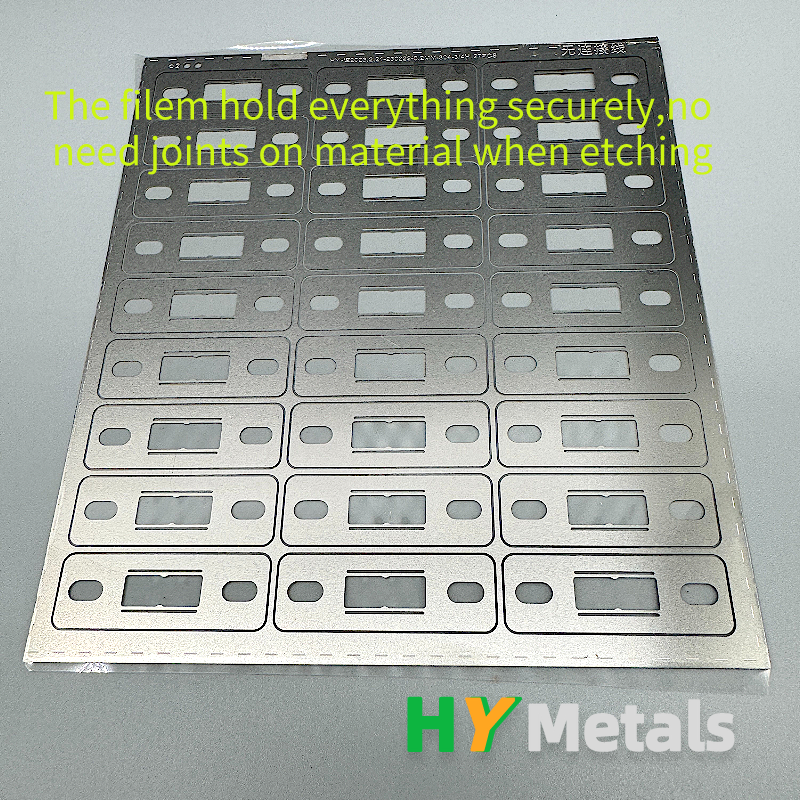

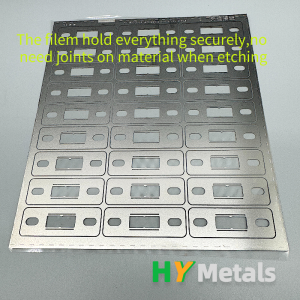

HY Metals has introduced a cutting-edge solution that eliminates the need for traditional joints when etching multiple parts onto sheet metal. This innovative method involves using a special film that is applied to the material before the etching process begins. The film acts as a protective layer, holding everything securely in place during the etching process, eliminating the need for separate joints. As a result, key decorative components can be etched without subsequently removing the connection points, ensuring edges remain smooth and pristine.

Advantages of special membranes:

The application of special films in the etching process has many advantages and can significantly improve the efficiency and quality of the etching process. By holding all components securely in place, the film eliminates the labor-intensive task of removing joints after etching, streamlining production workflow and reducing manual intervention. Additionally, with no joining points, the surface finish of key decorative components is seamless and uniform, meeting the highest standards of aesthetic and functional excellence.

Accuracy and consistency:

The use of special films underscores HY Metals’ unwavering commitment to etching precision and consistency. By ensuring that all parts remain securely fastened to the plate throughout the etching process, the innovative solution guarantees that each part retains its precise dimensions and intricate details without any compromise. This level of precision is essential to meet the stringent requirements of customers in different industries where perfect etched products are crucial.

Versatility and customization:

In addition to the impact on key decorative components, the application of special films opens up new possibilities for versatility and customization of etching. HY Metals’ ability to safely etch multiple parts without the constraints of traditional joint points allows it to accommodate a wider range of designs, geometries and configurations to meet each customer’s unique needs. This flexibility allows customers to explore innovative concepts and complex patterns with confidence that the etching process will deliver superior results without limitations.

Iin conclusion:

By reimagining the etching process with the introduction of specialized thin-film solutions, HY Metals sets a new standard for precision etching, improving the quality and efficiency of etched products. By eliminating the need for connection points and ensuring seamless part retention, this innovative approach exemplifies HY Metals’ commitment to pushing the boundaries of custom manufacturing and delivering superior solutions to its customers. As the industry continues to evolve, HY Metals remains at the forefront, driving innovation and excellence in precision etching.

Finally, this article highlights the precision etching services provided by HY Metals, emphasizing the company’s commitment to quality, craftsmanship, and custom manufacturing expertise. This content is designed to showcase the versatility and superior quality of etched products while positioning HY Metals as an industry-leading supplier.