Technical Points

-

Powder coating finish for sheet metal parts

1. Why choose Powder coating finish for a sheet metal part Powder coating is a popular finishing technique for sheet metal parts due to its many advantages. It involves applying a dry powder to the surface of a metal part and then curing it under heat to form a durable protective coating. Here ar...Read more -

Here are some special features that are challenging for precision sheet metal fabrication

There are some special structures or features that are challenging to fabricate for sheet metal prototype parts: 1. Lance (刺破) In sheet metal fabrication, a lance is a function that creates small, narrow cuts or slits in sheet metal. This cutout is carefully designed to allow the metal t...Read more -

Three methods to create threads in sheet metal parts:Tapping,Extruded Tapping and Riveting nuts

There are several ways to create threads in sheet metal parts. Here are three common methods: 1. Rivet Nuts: This method involves the use of rivets or similar fasteners to secure a threaded nut to a sheet metal part. Nuts provide a threaded connection for a bolt or screw. This method is suitabl...Read more -

Understanding Color Changes in Aluminum Anodization and Its Control

Aluminum anodizing is a widely used process that enhances the properties of aluminum by forming a protective oxide layer on its surface. The process not only provides corrosion resistance but also colors the metal. However, a common problem encountered during aluminum anodization is color var...Read more -

The Advantages of Laser Cutting over Water Jet and Chemical Etching for Precision Sheet Metal Fabrication

Introduction: Precision in sheet metal fabrication plays a crucial role in delivering high-quality results. With multiple cutting methods available, such as laser cutting, water jet cutting, and chemical etching, it’s important to consider which technique provides the most advantages. In th...Read more -

Why choose laser cutting for your precision sheet metal prototyping fabrication?

Precision sheet metal laser cutting revolutionizes manufacturing by delivering advanced cutting capabilities in an efficient and precise manner. This technology is proving critical in various industries including automotive, aerospace, electronics, medical and ...Read more -

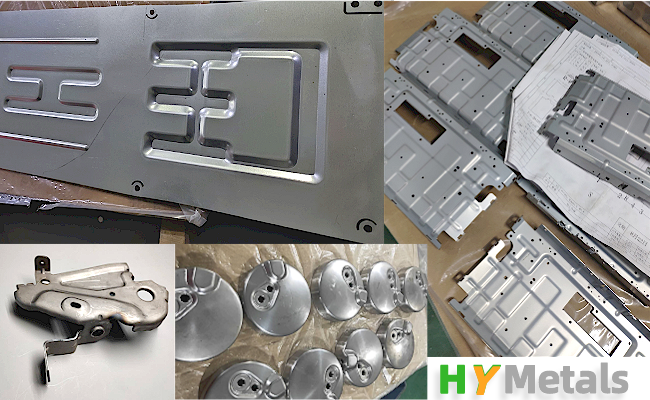

Overcome Challenges and Master the Keys to Precision Rapid CNC Machined Part

Production introduce In today’s fast-paced manufacturing environment, there is a growing demand for fast, precise CNC machined parts. This manufacturing process provides unparalleled precision, efficiency and consistency, making it ideal for a variety of industries including aerospace, auto...Read more -

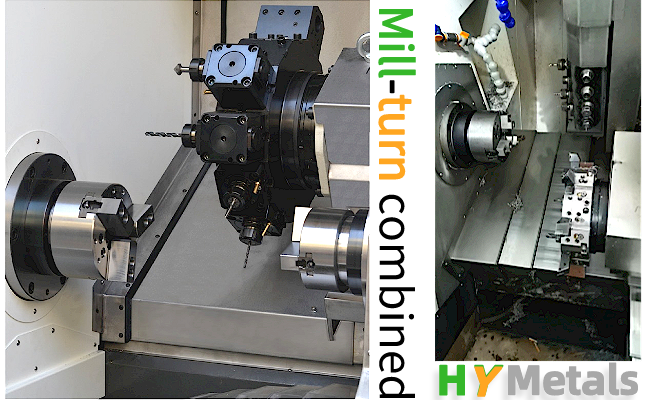

The advantages of using a milling-turning combined machine over 5-axis machine

The advantages of using a milling-turning combined machine over 5-axis machine These years, milling and turning combined machines become more and more popular, These machines have many advantages over traditional 5-axis machines. Here list some of the advantages of using a milling-turning combi...Read more -

Manual operation of many prototype parts that you do not know

Manual operation of many prototype parts that you do not know The prototyping phase is always a critical stage in the product development process. As a specialist manufacturer working on prototypes and low volume batches, HY metals is familiar with the challenges posed by this production ...Read more -

How important the skills and knowledge of a CNC programmer to the quality of CNC machined parts

CNC machining has revolutionized manufacturing, allowing precise and complex designs to be created efficiently and effectively. However, the success of CNC machining production depends heavily on the skill and experience of the CNC programmer. In HY Metals, which has 3 CNC factories and more...Read more -

Why do we need to add ribs to sheet metal parts and how prototype it?

For Sheet metal parts, adding stiffeners is critical to ensuring their strength and durability. But what are ribs, and why are they so important to sheet metal parts? Also, how do we make the ribs during the prototyping stage without using stamping tools? First, let’s define what a rib i...Read more -

The difference between precision sheet metal fabrication and rough sheet metal fabricaiton

Precision sheet metal fabrication and rough sheet metal fabrication are two distinct processes that require different levels of expertise and specialized equipment. In this article, we explore the differences between these processes and highlight the advantages of precision sheet metal fabricati...Read more