-

Introducing our latest custom precision sheet metal parts: Elevate your prototyping experience

At HY Metals, we are committed to providing innovative solutions to meet the ever-changing needs of our customers. Our new custom precision sheet metal parts, including black powder-coated covers with rivet nuts and clear-anodized aluminum chassis components, exemplify our dedication to quality and precision.

If you’re looking for a reliable partner for your sheet metal prototyping needs, look no further than HY Metals. Contact us today to learn more about our capabilities and how we can help make your project a reality!

HY Metals provide one-stop custom manufacturing services including sheet metal fabrication and CNC machining, 14 years experiences and 8 fully owned facilities.

Excellent Quality control, short turnaround, great communication.

Send your RFQ with detailed drawings today. We will quote for you ASAP.

WeChat:na09260838

Tell:+86 15815874097

Email:susanx@hymetalproducts.com

-

High Quality custom aluminum sheet metal cover with sandblasting and clear anodizing

Dimension: Custom according to design drawings

Tolerance for sheet metal bending: +/- 0.02mm

Material: Copper,brass,stainless steel,aluminum,steel,SPPC,SGCC,SECC,SPHC,cold rold steel,mild steel

Finishe: Sandblasting,anodizing,chemical film,chromate,plating,anodizing,on-demands

QTY: From 1 pcs prototyping to thousands series production

Application:Electronic,medical,aerospace,automation,auto

-

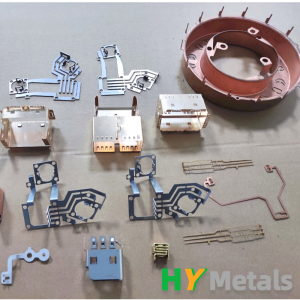

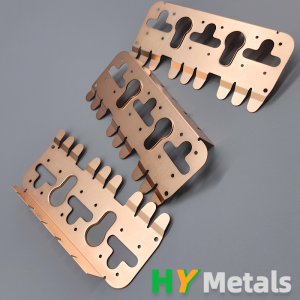

Precision custom sheet metal electronic contactor parts

The first of these innovative products is a 6 mm diameter electronic contact component with a conductive claw ring. The precision bending required to form a closed circle at the end of this part is a testament to HY Metals’ advanced manufacturing capabilities. The part’s intricate design and small size present unique production challenges, but our team of skilled craftsmen and state-of-the-art machinery ensure that each piece meets the precise specifications listed in the drawing.

-

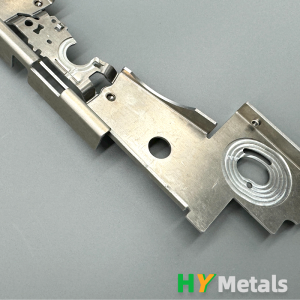

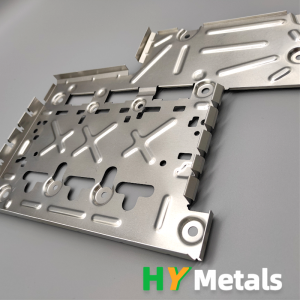

A Custom Sheet Metal Bracket Having Precision CNC Machining areas on several locations

HY Metals recently completed a project involving custom sheet metal parts made of Al5052 for automotive brackets.

After being laser cut, bent and riveted, the bracket required precision machining in four specific areas to create stepped circles. These stepped circles are necessary to accommodate the electronic components for the next stage of assembly. Despite the challenges of maintaining machining tolerances after bending, HY Metals successfully executed the project, ensuring a high-quality result.

-

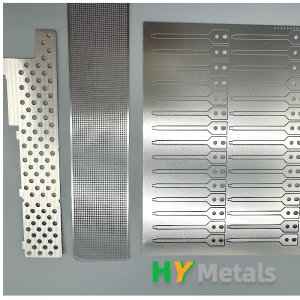

Precision Metal Etching Services from HY Metals: Seamless Part Fixing Solutions

HY Metals has introduced a cutting-edge solution that eliminates the need for traditional joints when etching multiple parts onto sheet metal. This innovative method involves using a special film that is applied to the material before the etching process begins. The film acts as a protective layer, holding everything securely in place during the etching process, eliminating the need for separate joints. As a result, key decorative components can be etched without subsequently removing the connection points, ensuring edges remain smooth and pristine.

-

High Precision and Customization with HY Metals: Leading Custom Sheet Metal Automotive Parts and Busbars

One of the main products manufactured by HY Metals is busbars for automobiles.

Busbars are important components that provide efficient and reliable electrical conductivity in electrical systems.

With advanced machinery and skilled personnel, HY Metals provides tailor-made solutions for custom sheet metal auto parts and busbars. Whether it’s a complex design or specific dimensional requirements, the company’s engineers and technicians have the expertise to develop and produce custom products.

This flexibility allows automakers to build products to their precise specifications, ensuring a perfect fit and optimal performance.

-

HY Metals is a leading sheet metal fabrication services provider with an impressive infrastructure and Professional service

HY Metals is a leading sheet metal fabrication services provider with an impressive infrastructure including four state-of-the-art sheet metal factories. Our facility has over 300 machines capable of handling the full spectrum of sheet metal processing from cutting to finishing.Be it steel, aluminum, brass or any other sheet metal, we have the expertise and machinery to manufacture parts from 1mm to 3200mm with exceptional precision and accuracy.

Our dedicated team of experts and technicians have the knowledge, skills and technical acumen required to deliver outstanding results, no matter how complex the project. From complex prototyping to large-scale production, we are committed to delivering custom solutions that embody the highest precision and attention to detail. By working closely with our clients, we ensure that their unique needs are met with maximum satisfaction and efficiency.

-

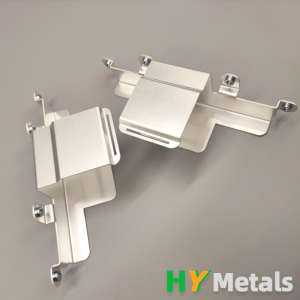

Sheet Metal Prototyping: High precision sheet metal brackets aluminum bracket sheet metal parts

Aluminum Sheet Metal Brackets. Constructed from AL5052 aluminum and coated with a clear chromate film, these brackets reflect the company’s commitment to precision and surface protection. Even after multiple processes such as cutting, bending, chemical coating, riveting, etc., the bracket is still intact. HY Metals pays meticulous attention to every step of the production process to ensure that there are no scratches or damage.

-

High precision sheet metal parts copper contactors sheet metal copper connectors

Part Name High precision sheet metal parts copper contactors sheet metal copper connectors Standard or Customized Customized Size 150*45*25mm,according to design drawings Tolerance +/- 0.1mm Material Copper, brass, beryllium copper, bronze, copper alloy Surface Finishes Sandblast, black anodizing Application Sheet metal prototype, electronics Process Laser cutting-Bending-welding-sandblasting-anodizing -

Custom Manufacturing service for Sheet Metal Prototype parts aluminum auto parts

Part Name High precision sheet metal prototype aluminum parts Standard or Customized Customized Size 275*217*10mm,according to design drawings Tolerance +/- 0.1mm Material Aluminum,AL5052,alloy Surface Finishes Clear anodizing Application Sheet metal prototype, auto parts Process Laser cutting-Forming-cutting -Bending -Anodizing -

Stainless steel sheet metal bracket with black powder coating custom sheet metal parts

Part Name Stainless steel sheet metal brackets with black powder coating Standard or Customized Customized Size 385*75*12mm,2.5mm thickness, according to design drawings Tolerance +/- 0.1mm Material Stainless steel, SUS304 Surface Finishes Powder coating black Application Sheet metal prototype, arm brackets Process Laser cutting-Forming-cutting -Bending -Anodizing -

Custom galvanized steel sheet metal brackets for Electrical Boxes

Part Name Custom galvanized steel sheet metal brackets for Electrical Boxes Standard or Customized Customized Size 420*100*80mm,1.5mm thickness, according to design drawings Tolerance +/- 0.1mm Material Galvanized steel,SGCC,SECC Surface Finishes Galvanized Application Brackets for Electrical Boxes Process Laser cutting-Forming-Bending -Riveting