1. Why choose Powder coating finish for a sheet metal part

Powder coating is a popular finishing technique for sheet metal parts due to its many advantages. It involves applying a dry powder to the surface of a metal part and then curing it under heat to form a durable protective coating. Here are some reasons to choose powder coating for sheet metal parts:

Durability: Powder coating provides a tough and resilient finish that is highly resistant to chips, scratches and fading, making it ideal for sheet metal parts that may be subject to wear and tear.

Corrosion resistance: The coating acts as a barrier against moisture and chemicals, protecting the metal sheet from rust and corrosion, thereby extending the service life of the parts.

Aesthetics: Powder coatings are available in a variety of colors, textures and finishes, allowing for customization and enhancing the visual appeal of sheet metal parts.

Environmental benefits: Unlike traditional liquid coatings, powder coatings contain no solvents and emit negligible volatile organic compounds (VOCs), making them an environmentally friendly choice.

Cost-Effectiveness: Powder coating is an efficient process with minimal material waste, reducing the overall production cost of sheet metal parts.

Uniform coverage: Electrostatic application of the powder ensures even coverage, resulting in a smooth and consistent finish on the sheet metal.

Overall, powder coating’s durability, aesthetics, environmental friendliness, and cost-effectiveness make it a compelling choice for sheet metal part finishing across a variety of industries.

2. The texture effect for powder coating

The most common powder coating texture effects for sheet metal parts include:

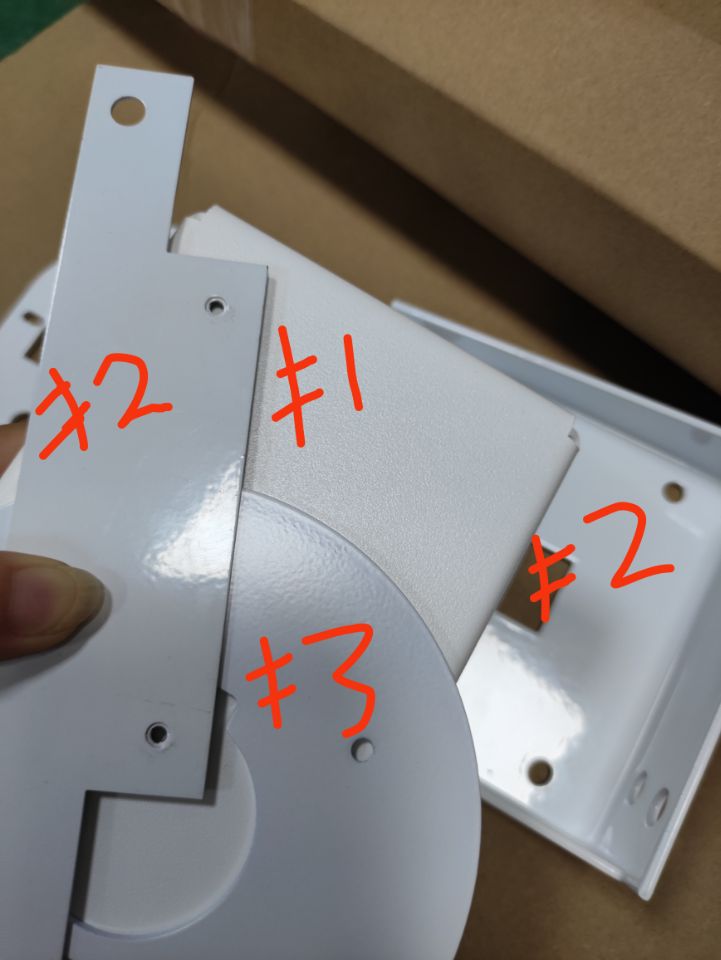

#1 Sandtex: A textured finish that resembles the look and feel of fine-grained sand, providing a tactile and visually appealing surface.

#2 Smooth: Classic, even surface provides a smooth, clean look.

#3 Matte: A non-reflective finish with a subtle low-gloss appearance.

#4 Wrinkle: A textured finish that creates a wrinkled or pleated appearance, adding depth and visual interest to a surface.

#5 Leatherette: A textured finish that replicates the look and feel of leather, adding a refined tactile element to sheet metal parts.

These textural effects can be achieved through a variety of powder coating techniques and can be customized to meet specific design preferences and functional requirements.

3. How to match a required powder coating color

Powder coating color matching for custom sheet metal fabrication involves the process of creating a specific color or shade that meets the customer’s requirements. Here’s how it’s usually done:

Color matching process: This process starts with the customer providing color samples (such as paint chips or real objects) for reference. Powder coating manufacturers then use color matching equipment and technology to analyze the sample and formulate a custom powder coating color that closely matches the provided reference.

Customized formulations: Based on analysis, manufacturers create custom powder coating formulations by mixing different pigments and additives to achieve the desired color. This may involve adjusting pigment concentration, texture and gloss to achieve an accurate match.

Testing and Validation: Once a custom color formula is ready, manufacturers typically apply the powder coating to sheet metal samples for testing. Customers can then evaluate the samples to ensure the color meets their expectations under different lighting conditions.

Production: Once the color match is approved, the sheet metal parts are painted to the customer’s specifications during production using a custom powder coating formula.

Benefits of powder coating color matching for custom sheet metal fabrication:

Customization: It allows customers to achieve specific color requirements, ensuring the finished sheet metal part matches their brand or design preference.

Consistency: Custom color matching ensures all sheet metal parts are the same color, ensuring consistency in manufactured components.

Flexibility: Powder coatings are available in a variety of color options, allowing for nearly unlimited customization to meet the unique needs of different industries and applications.

Overall, powder coating color matching for custom sheet metal fabrication enables manufacturers to provide customized solutions that meet customer aesthetic and functional needs.

In our production, HY Metals usually need a RAL or Pantone color number at least, and also need the texture from customers to match a good powder coating surface effect.

For some critical requirements, we will have to get a sample (paint chips or real objects) for color matching reference.

Post time: May-06-2024