High Precision Plastic Parts custom machined plastic parts

Custom CNC machined plastic parts are becoming more and more common in various industries. These plastic parts are used in different applications and offer several advantages over other materials. Traditional plastics such as nylon, FR4, PC, acrylic, and engineering plastics have been widely used in many industries. However, with the development of new plastic materials, options such as POM and PEEK are now available, offering greater strength and durability.

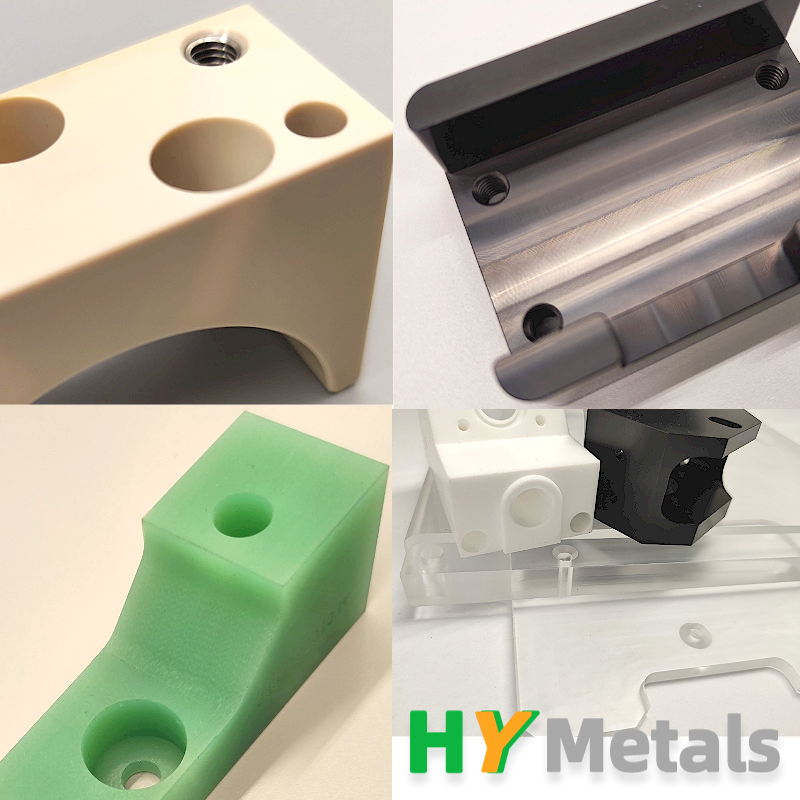

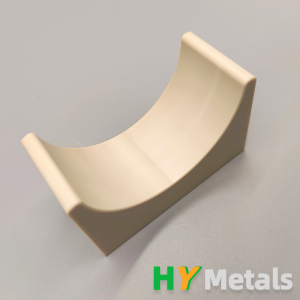

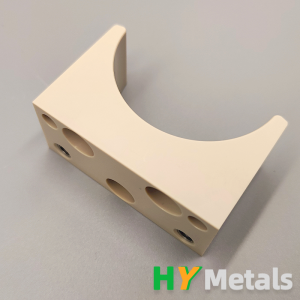

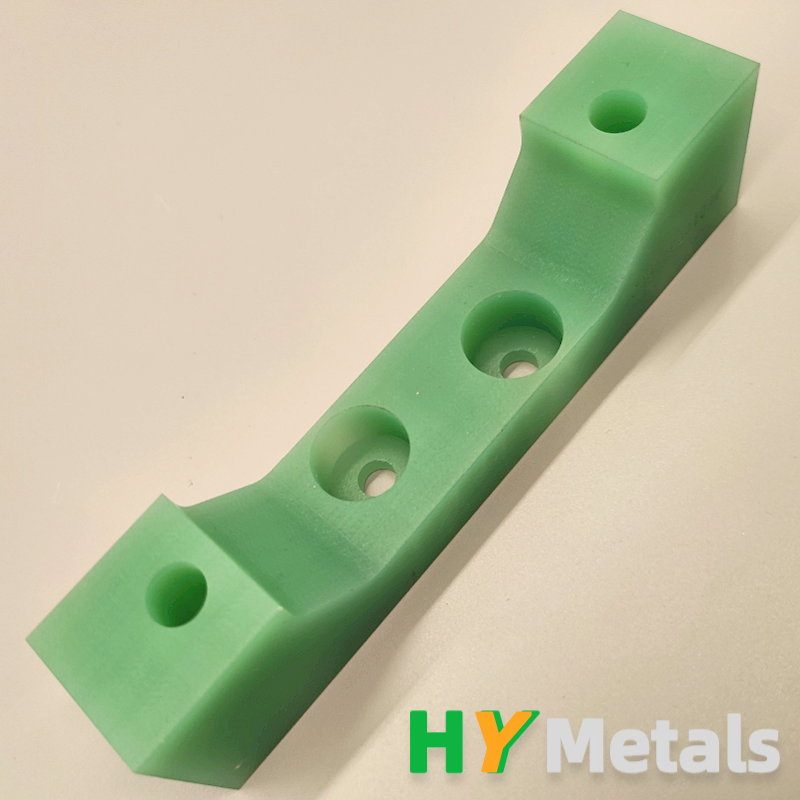

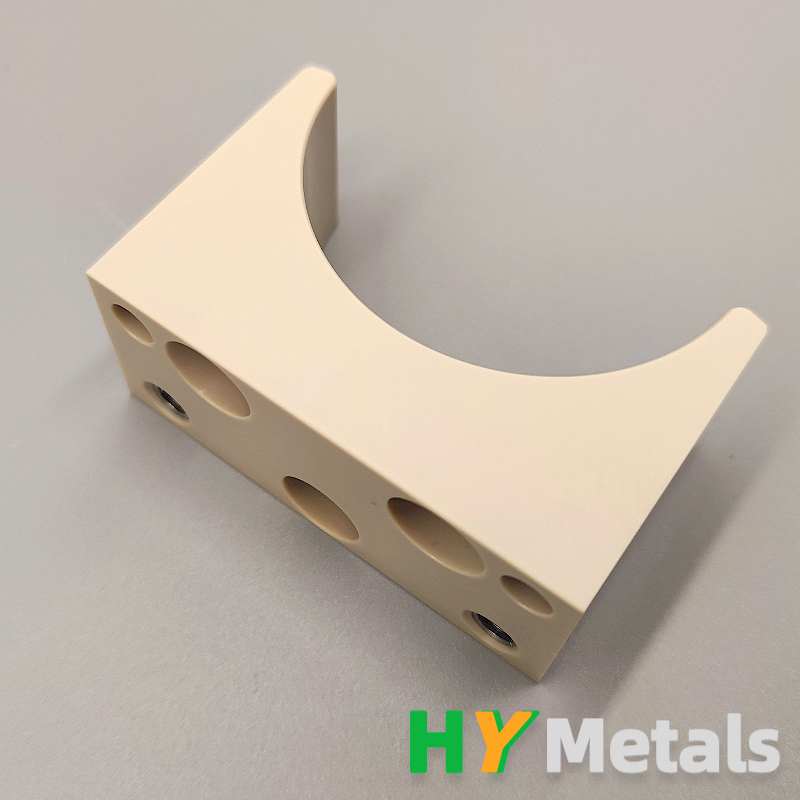

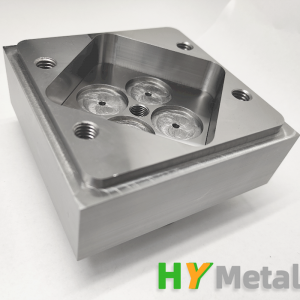

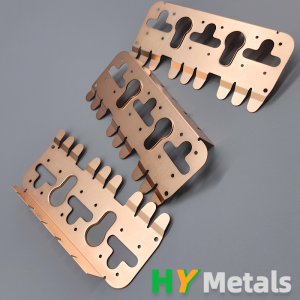

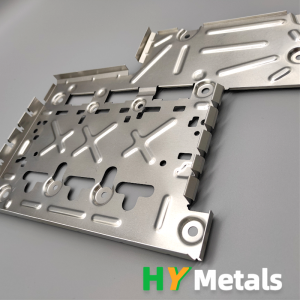

HY Metals, a manufacturing company specializing in sheet metal and CNC machining, offers products machined from these new plastic materials. Here are some plastic parts machined from different plastic materials:

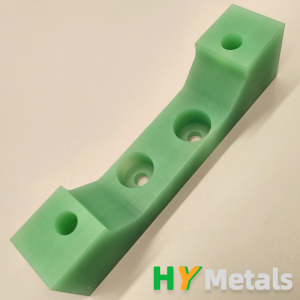

FR4: Green plastic parts are processed with FR4. The material is a composite material made of woven glass fiber cloth as the base material and epoxy resin adhesive. It is widely used in electronic equipment due to its high insulating properties and excellent mechanical, thermal and chemical resistance.

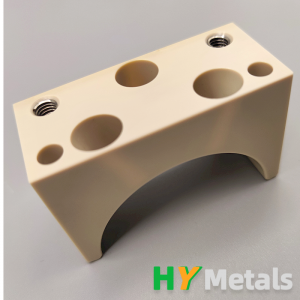

PEEK: The brown plastic part contains the coil insert and is made of PEEK, a hard and expensive material with excellent mechanical and thermal properties. PEEK can withstand high temperatures and pressures, making it an ideal material for the aerospace, automotive and oil and gas industries.

POM: Black plastic parts are machined from POM (also known as acetal), a thermoplastic with excellent mechanical strength, stiffness and dimensional stability. It is widely used in gears, bearings and other high load applications.

All these plastic parts are high-precision parts processed by CNC. Precision is critical in the manufacture of plastic parts, and CNC machining ensures precision and consistency in every part. CNC machining is an economical, efficient and accurate method of manufacturing parts of varying degrees of complexity.

HY Metals has more than 150 CNC milling machines and lathes, which can provide high-precision parts for metal and plastic materials. HY Metals has 3 CNC processing workshops and 4 sheet metal factories, which can support orders of various sizes from different customers. We provide customized solutions according to customer requirements, ensuring high quality products that meet or exceed all specifications.

In summary, custom CNC machined plastic parts offer several advantages over traditional materials.The use of high-performance engineering plastics such as PEEK and POM increases strength, durability and abrasion resistance.CNC machining ensures accuracy, consistency and reliability of each part.

As a leading manufacturer of sheet metal and CNC machined parts, HY Metals can supply high quality parts made of various materials to meet customers’ requirements. Contact us today to find out how we can help with your project.