Customized metal parts which require no coating in specified areas

Description

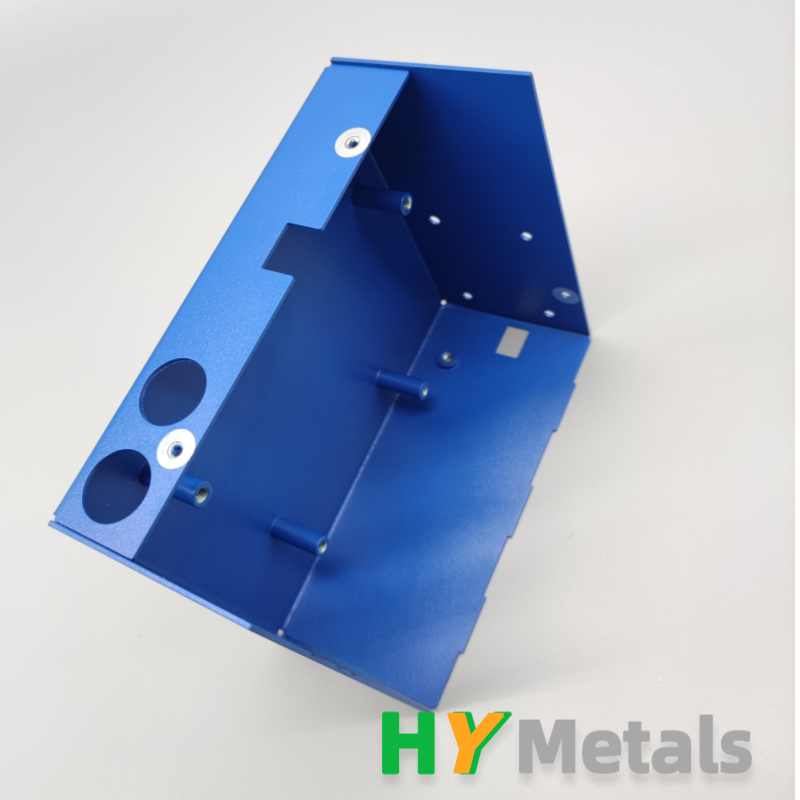

| Part Name | Custom metal parts with coating |

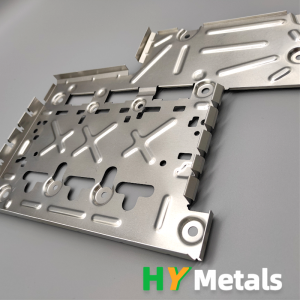

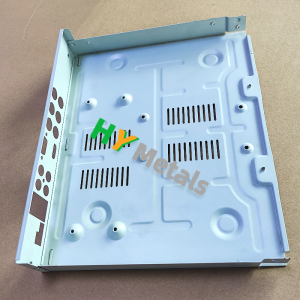

| Standard or Customized | Customized sheet metal parts and CNC machined parts |

| Size | According to drawings |

| Tolerance | According to your requirement, on demand |

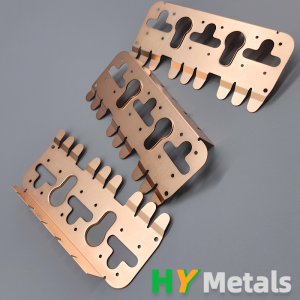

| Material | Aluminum, steel, stainless steel, brass, copper |

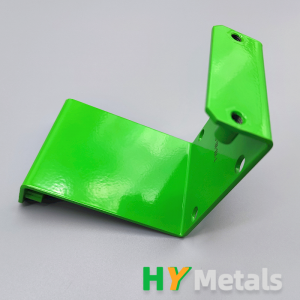

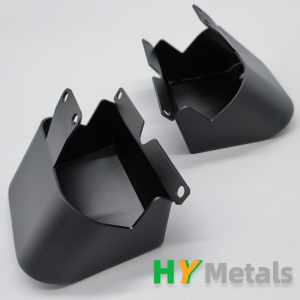

| Surface Finishes | Powder coating, plating, anodizing |

| Application | For a wide range of industry |

| Process | CNC machining, sheet metal fabrication |

How to deal with No coating requirements in specified location for metal parts

When it comes to metal parts, coatings serve several key purposes. It enhances the appearance of parts, protects them from external elements such as corrosion and wear, and extends their service life. Typically, metal parts are powder coated, anodized or plated. However, some sheet metal or CNC machined parts may require the entire surface to be coated except in those locations when conductivity is required in specific areas of the part.

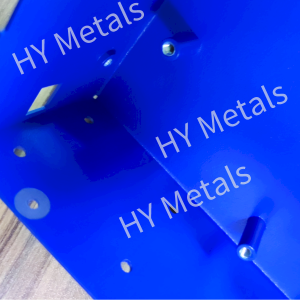

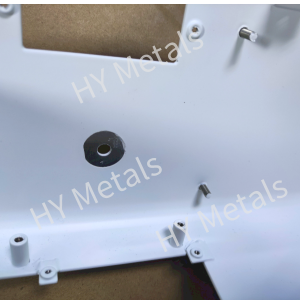

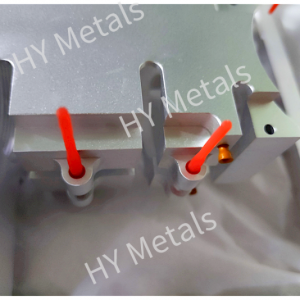

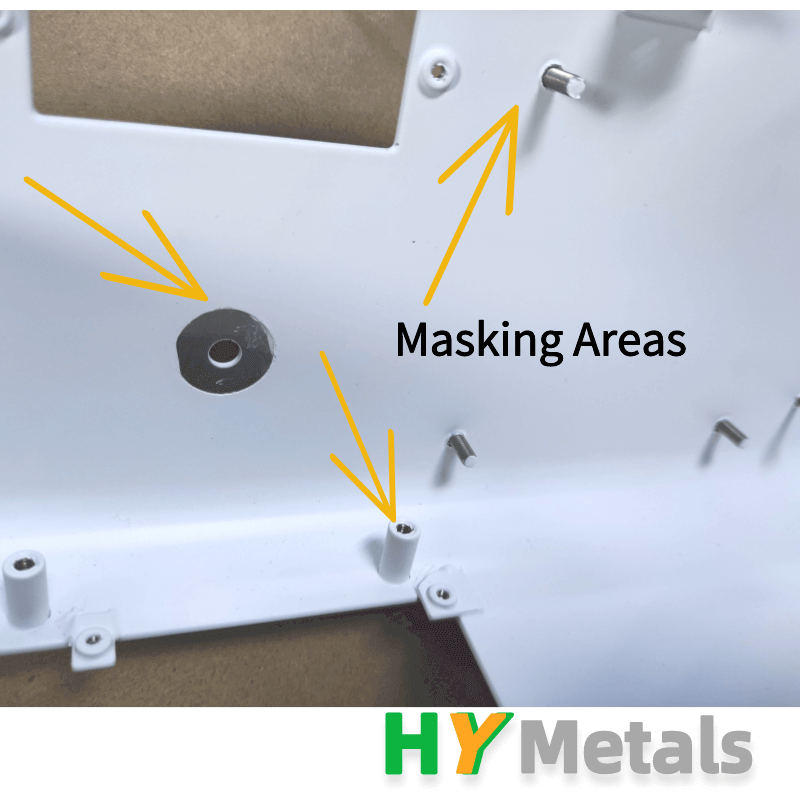

In this case, it is necessary to mask those places that do not require coating. Masking needs to be done carefully to ensure that the masked areas are free of paint and that the remaining areas are perfectly coated. Here are some tips to ensure the coating process goes smoothly.

Paint masking

When powder coating, masking the area with tape is the most convenient way to protect unpainted areas. First, the surface needs to be properly cleaned and then covered with tape or any thermoplastic film that can withstand high temperatures. After coating, the tape needs to be removed carefully so that the coating does not come off. Masking in the powder coating process requires precision to improve the quality of the final product.

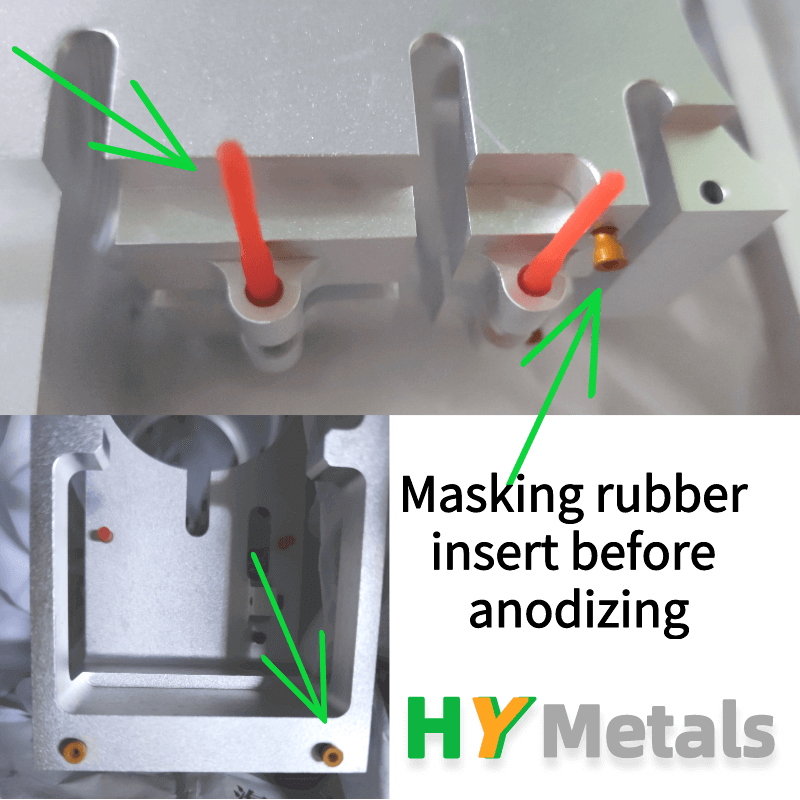

Anodizing and Plating

During the process of anodizing aluminum parts, an oxide layer is formed on the surface of the metal that enhances appearance while also providing corrosion resistance. Also, use an anti-oxidant glue to protect the part during the masking process. Anodized aluminum parts can be masked using adhesives such as nitrocellulose or paint.

When plating metal parts, it is necessary to cover the threads of nuts or studs to avoid coating. Using rubber inserts would be an alternative masking solution for the holes, allowing the threads to escape the plating process.

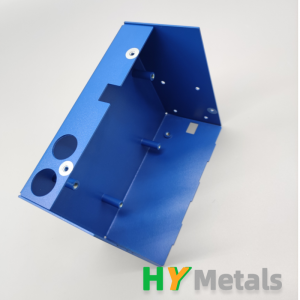

Custom metal parts

When manufacturing custom metal parts, it is critical to ensure the parts meet the exacting specifications of the customer. Accurate masking techniques are critical for sheet metal and CNC machined parts that do not require coating in specific areas. Engineering precision coatings means paying attention to intricate details and the quality of the materials used. After all, coating errors can lead to wasted parts and unexpected additional costs.

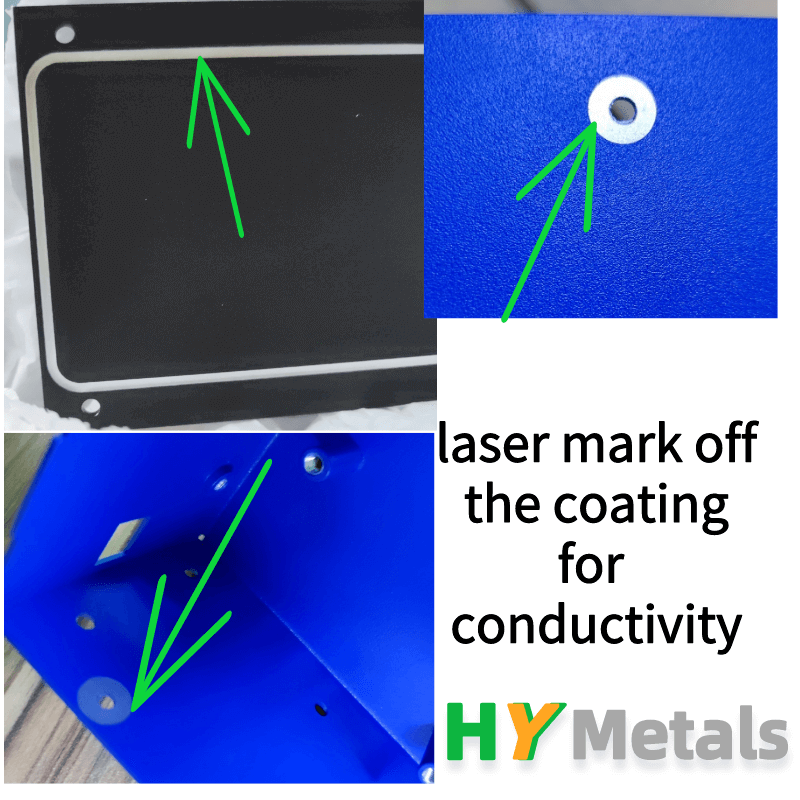

Laser marking painting

Any product that can be laser marked offers significant advantages when coated. Laser marking is an excellent method for removing coatings during assembly, often after masking locations. This method of marking leaves a darker etched image on the metal part that looks nice and contrasts with the surrounding area.

In summary, masking is essential when coating custom metal parts that do not have coating requirements at designated locations. Whether you are using anodizing, electroplating or powder coating, different products require unique masking techniques to ensure the quality of the final product. Be sure to take careful masking precautions before proceeding with the coating process.