-

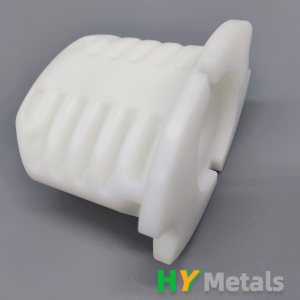

High Quality Custom CNC Machining Plastic Parts OEM POM Components

Customized size:φ190mm*100mm*40

Material: White POM

Tolerance:+/- 0.01mm

Process:CNC machining, CNC milling

Unlike metal, plastic is softer and deforms more easily when processed. This makes it more difficult to control the tolerances of machined parts. Fortunately, our team of experts at HY metals has the experience and expertise to ensure that each machined part is correct and perfect, ensuring our clients receive high-quality custom plastic parts to their specifications.

-

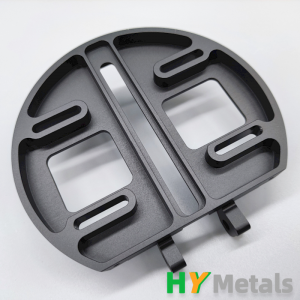

OEM High Precision CNC Machining Services for Custom CNC Machining Aluminum Parts

OEM High Precision CNC Machining Services for Custom CNC Machining Aluminum Parts

Customized size:φ150mm*20mm

Material:AL6061-T6

Tolerance:+/- 0.01mm

Process:CNC machining, CNC milling

Finish:Sandblast+ black anodized

-

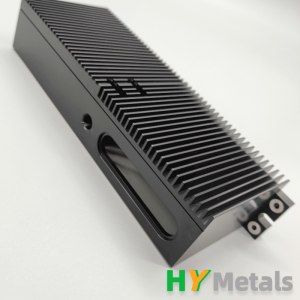

Custom CNC Machining Heatsink Prototype Aluminum Radiator Parts

Custom CNC Machining Heatsink Prototype Aluminum Radiator Parts

Customized size:φ220mm*80mm*50mm

Material:AL6061-T6

Tolerance:+/- 0.01mm

Process:CNC machining, CNC milling

-

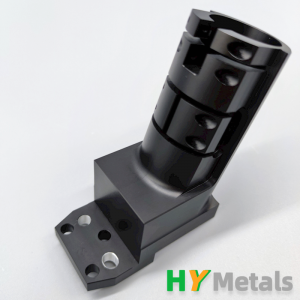

High precision OEM CNC machined camera component camera prototype parts

High precision OEM CNC machined camera component camera prototype parts

Customized size:φ180mm*60mm

Material:AL6061-T6

Tolerance:+/- 0.01mm

Process:CNC machining, CNC milling

-

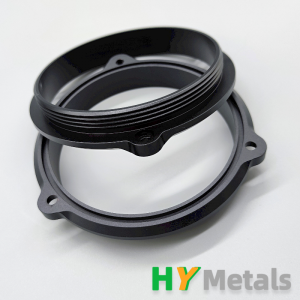

High Precision CNC turned aluminum part with sandblasted and black anodized for camera prototypes

Camera round flanges manufactured by HY Metals are made of sandblasted and black anodized aluminum.

Customized size:φ150mm*20mm

Material:AL6061-T651

Tolerance:+/- 0.01mm

Process:CNC turning, CNC milling

-

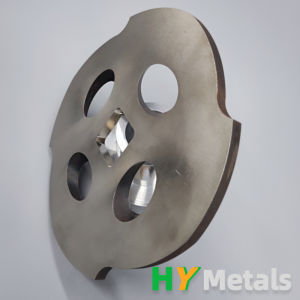

CNC Machining of 17-7 PH Stainless Steel: Best Precision Wire EDM

CNC Machining of 17-7 PH Stainless Steel: Best Precision Wire EDM

Customized size:φ200mm

Material:17-7PH

Tolerance:+/- 0.01mm

Process:CNC milling,wire EDM Cutting

-

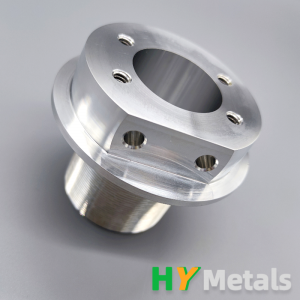

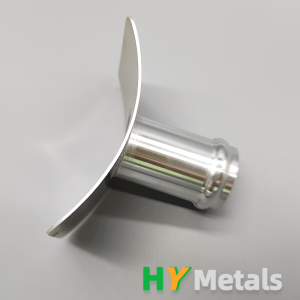

High precision CNC turning parts with machined external threads

High precision CNC turning parts with machined external threads

Customized size:φ100mm*150mm

Material:AL6061-T6

Tolerance:+/- 0.01mm

Process:CNC turning, CNC milling

-

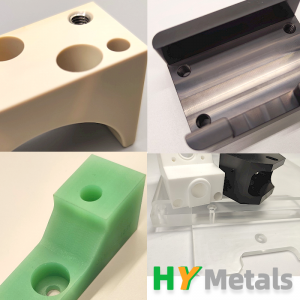

High Precision Plastic Parts custom machined plastic parts

Part Name High Precision Plastic Parts Machined Using Custom CNC Machining Standard or Customized Customized Size 120*30*30mm,according to design drawings Tolerance +/- 0.1mm Material PEEK, FR4, POM, PC, Acrylic, Nylon Surface Finishes As machined Application Aerospace, automotive and oil and gas industries Process CNC milling, CNC turning, CNC machining -

Custom sheet metal welding and assembly

Sheet Metal Fabrication Processes: Cutting, Bending or Forming, Tapping or Riveting, Welding and Assembly. Sheet metal assembly is the process after cutting and bending, sometimes it is after coating process. We usually assemble parts by riveting, welding, pressing fit and tapping to screw them together. Tapping and Riveting Threads are playing an important role in assemblies. There are 3 main methods to get threads: Tapping, riveting, install coils. 1. Tapping threads Tapping is a process ... -

High-quality sheet metal welded component Custom aluminum welding assembly

Part Name High-quality sheet metal welded component Custom aluminum welding assembly Standard or Customized Customized Size 80*40*80mm,according to design drawings Tolerance +/- 0.1mm Material Aluminum tubes and aluminum sheet metal Surface Finishes Clear chromate, chemical film Application Sheet metal prototype, brackets Process Laser cutting-bending-Forming tubs- welding-chromate -

Precision Sheet metal bending and forming process

Sheet Metal Fabrication Processes: Cutting, Bending or Forming, Tapping or Riveting, Welding and Assembly. Bending or Forming Sheet metal bending is the most important process in the sheet metal fabrication. It is a process of changing the material angle into a v-shaped or U-shaped, or other angles or shapes. The bending process makes the flat parts to be a formed part with angles, radius, flanges. Usually sheet metal bending includes 2 methods: Bending by Stamping Tooling and Bending by ben... -

High precision metal stamping work include Stamping, Punching and Deep-Drawing

Metal stamping is a process with stamping machines and Toolings for mass production. It is more precision, more faster, more stable, and more cheaper unit price than laser cutting and bending by bending machines. Of course you need to consider the tooling cost first. According to the subdivision, Metal stamping is divided into ordinary Stamping, Deep drawing and NCT punching. Picture1: One corner of HY Metals stamping workshop Metal Stamping has the characteristics of high speed and precisio...