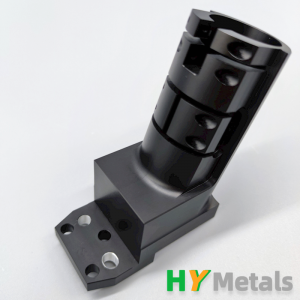

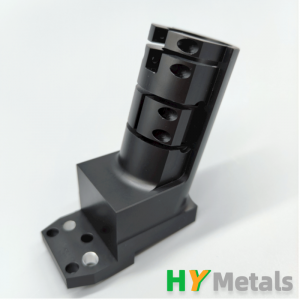

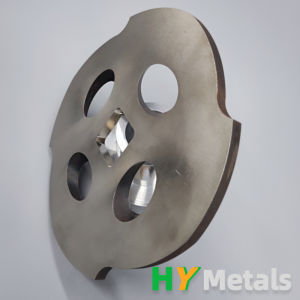

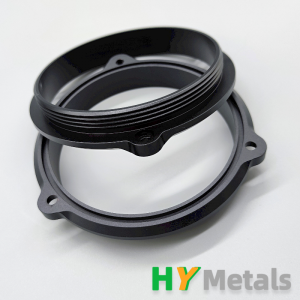

High precision OEM CNC machined camera component camera prototype parts

As the world continues to advance in technology, the demand for high-precision components continues to grow. The camera industry is no exception. To meet the demand for high-quality camera parts, HY Metals is a reliable custom fabrication supplier in China, specializing in custom sheet metal fabrication, rapid prototyping, and various metal parts and most plastic parts. One of the main services we offer is custom CNC machining of high precision camera components such as camera prototype parts and camera body parts.

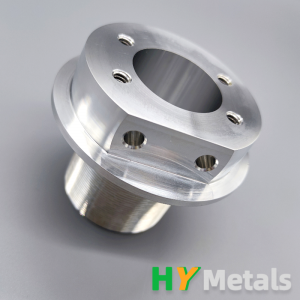

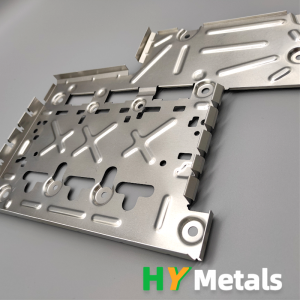

CNC machining is a manufacturing process that uses computer-controlled machines to create parts with high precision and accuracy. With this technology, HY Metals can produce custom metal parts to meet the specific needs of customers.

For camera prototype parts, CNC machining is especially useful. Through this process, HY Metals was able to quickly create a prototype to demonstrate the functionality of the camera part. This allows customers to test and modify designs before committing to larger production quantities. In addition, CNC machined camera prototype parts can be produced with high precision, ensuring that the final product meets the customer’s standards.

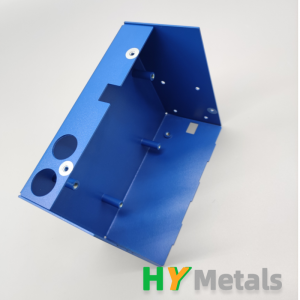

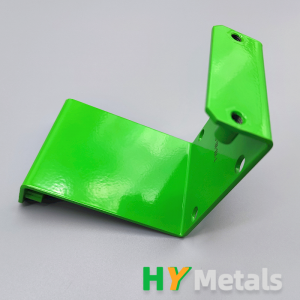

For camera body components, HY Metals uses aluminum 6061-T6 as the main material. This material is known for its high strength, light weight and excellent processing properties. Additionally, Aluminum 6061-T6 can be easily anodized, making it ideal for camera components requiring a black finish. Anodized parts provide a durable, corrosion-resistant finish that enhances their appearance.

Tight tolerances are another key factor when it comes to CNC machined camera body components. With tight tolerances, the camera parts fit together seamlessly to ensure they work properly. HY Metals has the technology and expertise to produce parts to exacting tolerances, allowing them to precisely meet the needs of their customers.

For camera components, surface finish is also important. A good surface finish can enhance the camera’s appearance and make it more visually appealing. Through CNC machining, HY Metals can produce camera parts with a smooth, high quality surface finish that meets customer specifications.

Overall, HY Metals provides a fast turnaround one-stop shop for high precision OEM CNC machining components. We have the technology, expertise and experience to produce custom camera assemblies that meet the specific needs of our customers. As a reliable custom manufacturing supplier in China, our commitment to quality, precision and speed makes us an ideal partner for businesses in the custom manufacturing industry.