Technical Points

-

CNC Machining Tool Wear Navigation: Maintaining Part Accuracy in precision machining

In the field of custom manufacturing, especially in precision sheet metal and CNC machining, the impact of tool wear on part accuracy is a key consideration that directly affects the quality of the final product. At HY Metals, we are committed to adhering to the highest quality management and pre...Read more -

Why choose to perform sheet metal prototyping in China?

The customers often choose to perform sheet metal prototyping in China for several reasons: 1.Cost-Effectiveness Compared to the West, China is generally considered cost-effective in customizing sheet metal prototypes for the following reasons: Labor costs: China’s labor costs are generally l...Read more -

Learn about Knurling for CNC turning parts

What is Knurling? Knurling is a key process for precision turned parts, providing a textured surface that enhances grip and appearance. It involves creating a pattern of straight, angular or diamond-shaped lines on the surface of a workpiece, usually using a lathe or knurling tool. The process ...Read more -

Laser Marking Machine Versatility in Custom Manufacturing Production

Laser marking offers several advantages over traditional marking methods such as screen printing, stamping, and labeling. Here are some of the main advantages of laser marking: 1. Precision and Versatility: Laser marking offers unparalleled accuracy and can engrave complex designs, logos and ...Read more -

Sheet Metal Welding:How HY Metals minimize the welding distortion

1.The importance of welding in sheet metal fabrication The welding process is very important in sheet metal manufacturing as it plays a key role in joining metal parts to create complex structures and products. Here are some points that highlight the importance of welding processes in sheet metal...Read more -

Minimize the visibility of the suspension points for aluminum anodizing

Anodizing aluminum parts is a common surface treatment that enhances their corrosion resistance, durability, and aesthetics. In our sheet metal and CNC machining production practice, there are lots of aluminum parts need to be anodized, both aluminum sheet metal parts and aluminum CNC machined p...Read more -

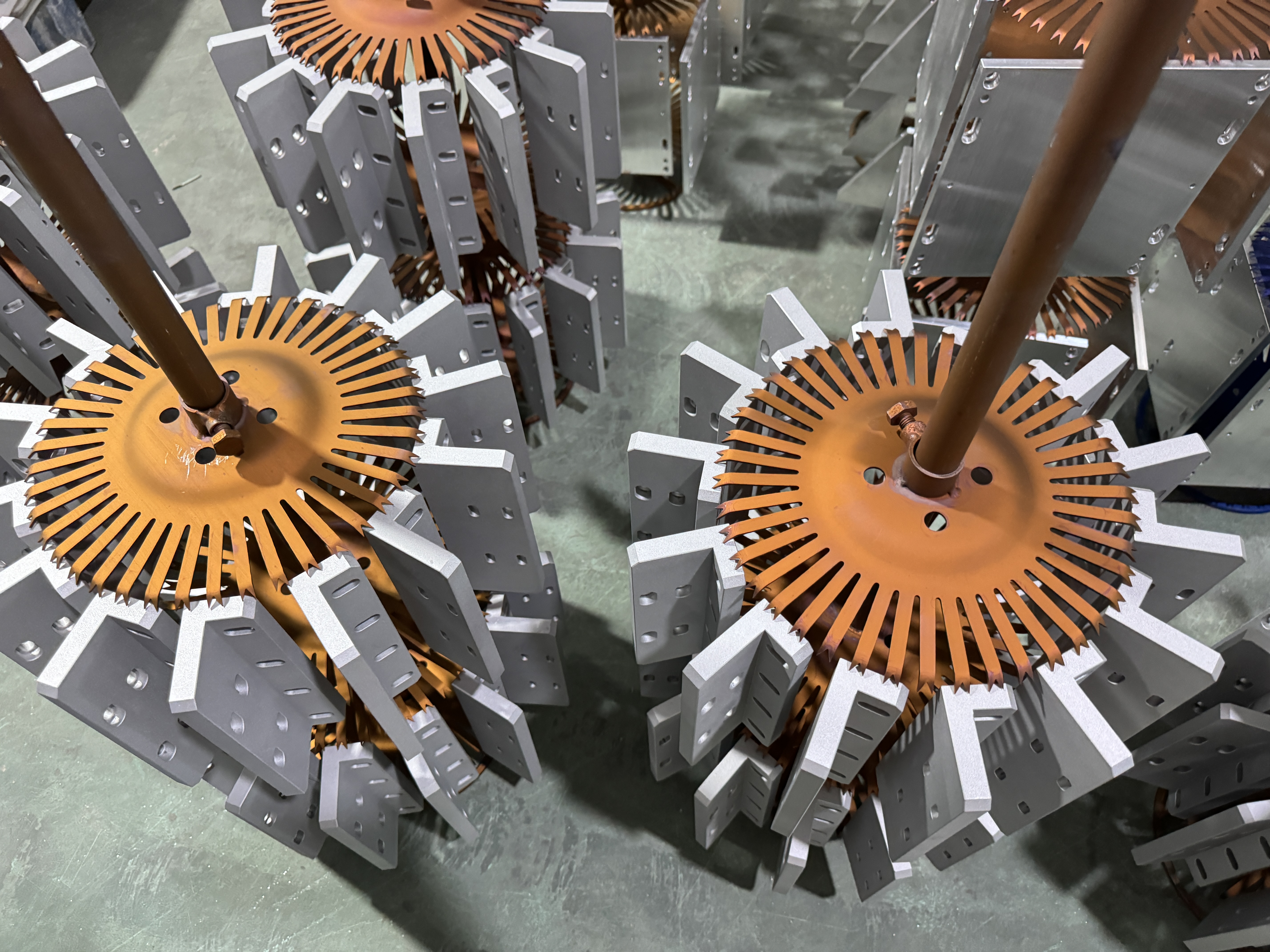

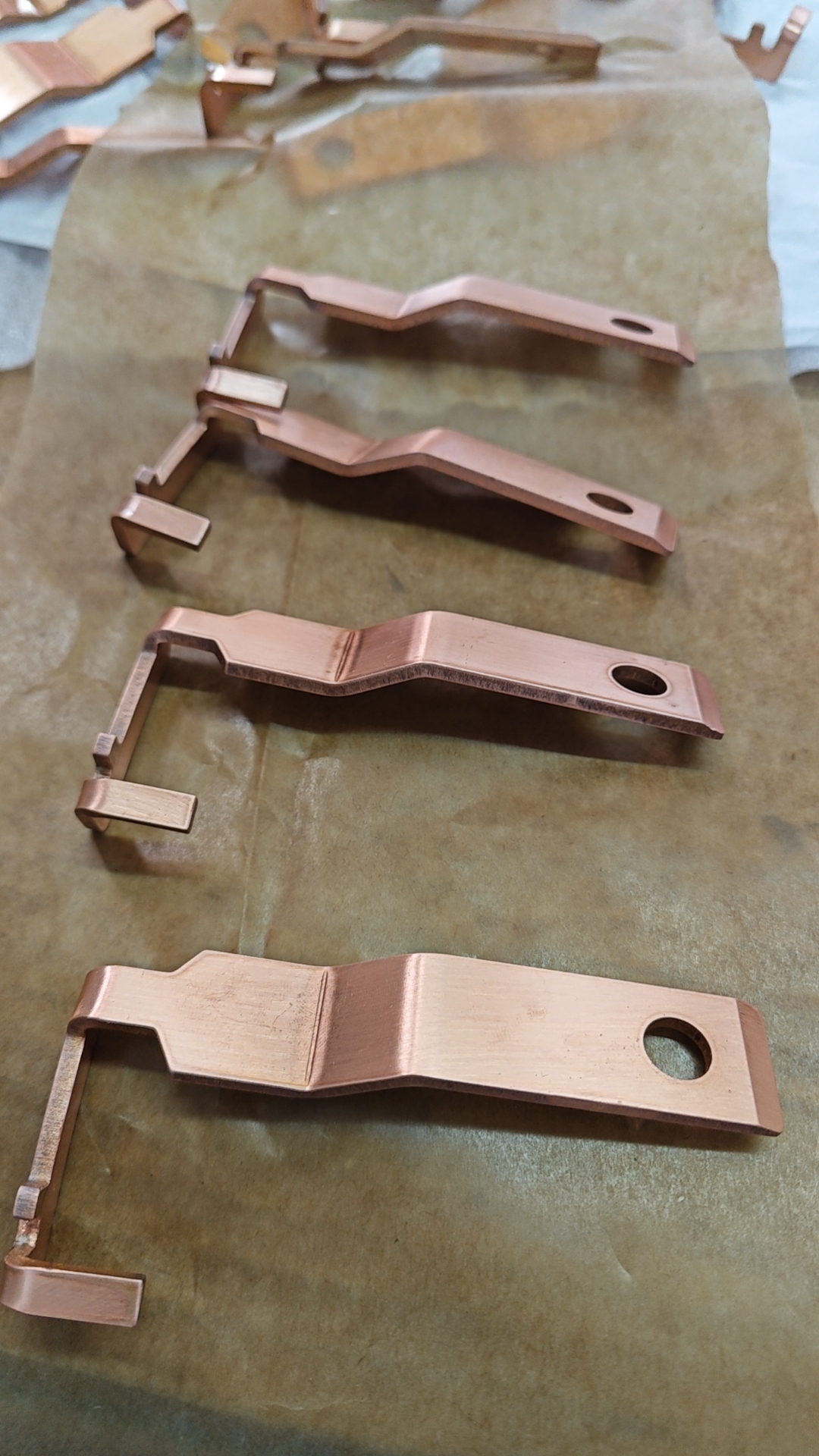

The increasing demands of sheet metal copper components for electric cars

The increasing demands for sheet metal copper components by electric cars Due to several key factors related to electrical systems and operating requirements, new energy electric vehicles require more copper or brass parts during the manufacturing process than traditional fuel vehicles. The trans...Read more -

Powder coating finish for sheet metal parts

1. Why choose Powder coating finish for a sheet metal part Powder coating is a popular finishing technique for sheet metal parts due to its many advantages. It involves applying a dry powder to the surface of a metal part and then curing it under heat to form a durable protective coating. Here ar...Read more -

Here are some special features that are challenging for precision sheet metal fabrication

There are some special structures or features that are challenging to fabricate for sheet metal prototype parts: 1. Lance (刺破) In sheet metal fabrication, a lance is a function that creates small, narrow cuts or slits in sheet metal. This cutout is carefully designed to allow the metal t...Read more -

Three methods to create threads in sheet metal parts:Tapping,Extruded Tapping and Riveting nuts

There are several ways to create threads in sheet metal parts. Here are three common methods: 1. Rivet Nuts: This method involves the use of rivets or similar fasteners to secure a threaded nut to a sheet metal part. Nuts provide a threaded connection for a bolt or screw. This method is suitabl...Read more -

Understanding Color Changes in Aluminum Anodization and Its Control

Aluminum anodizing is a widely used process that enhances the properties of aluminum by forming a protective oxide layer on its surface. The process not only provides corrosion resistance but also colors the metal. However, a common problem encountered during aluminum anodization is color var...Read more -

The Advantages of Laser Cutting over Water Jet and Chemical Etching for Precision Sheet Metal Fabrication

Introduction: Precision in sheet metal fabrication plays a crucial role in delivering high-quality results. With multiple cutting methods available, such as laser cutting, water jet cutting, and chemical etching, it’s important to consider which technique provides the most advantages. In th...Read more