At HY Metals, we pride ourselves on our commitment to quality and precision with every custom part we produce.

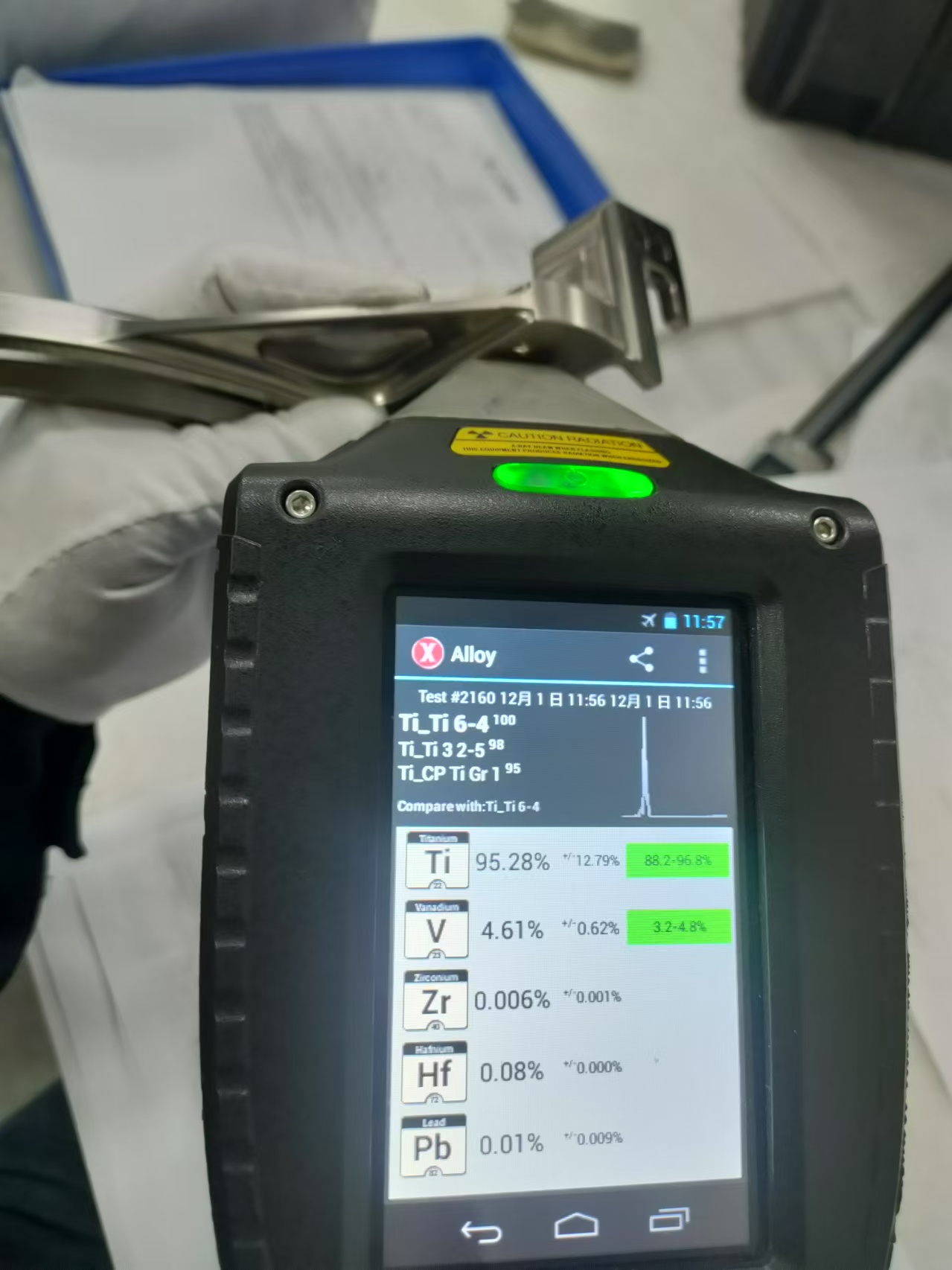

As a leader in the custom parts manufacturing industry, we understand that the integrity of our products begins with the materials we use. That’s why we’re excited to announce the addition of a state-of-the-art materials testing spectrometer to our facility to enhance our ability to ensure the right materials are used for all of your custom parts.

Importance of Material Verification

In manufacturing, material selection can significantly impact a product’s performance, durability, and overall success. Whether you are prototyping a new design or scaling up for volume production, using the right materials is critical. Misidentifying materials can lead to costly errors, delays and reduced product quality. This is where our new spectrometer comes into play.

What is a material detection spectrometer?

Material detection spectrometers are advanced analytical tools that allow us to identify and analyze the composition of a wide range of materials with unparalleled accuracy(including steel,aluminum,copper alloy,Titanium alloy and other materials). Unlike our previous X-ray scanners, which had limited functionality, this new spectrometer can test a wider range of materials, including metals, plastics and composites. It uses advanced technology to provide detailed information about the elemental composition of a sample, ensuring we can verify that the materials used meet the required specifications.

Strengthen our quality control processes

By integrating this cutting-edge technology, HY Metals has taken our quality control processes to the next level. Spectrometers allow us to conduct thorough material inspections, ensuring that every batch of material we receive meets standards. Not only does this help us maintain the highest quality of our products, but it also builds trust with our customers, letting them know we are committed to using only the best materials for their projects.

Advantages of prototyping and mass production

For our customers, our new spectrometer offers significant advantages. During the prototyping phase, we can quickly and accurately validate the materials used, allowing for faster iteration and adjustments. This means you can develop prototypes with confidence knowing the materials are exactly what you need for your design.

In mass production, spectrometers play a vital role in maintaining consistency and quality in large quantities of parts. By ensuring every material used in production is verified, we minimize the risk of defects and ensure every part meets the exacting standards our customers expect.

Committed to innovation

At HY Metals, we are committed to continuous improvement and innovation.

The addition of materials testing spectrometers is just one of the many ways we are investing in capabilities to better serve our customers. We believe that by leveraging advanced technology, we can improve our processes, improve product quality, and ultimately provide our customers with superior value.

In conclusion

As we embrace this new technology, we invite you to experience the HY Metals difference. Our new materials inspection spectrometer is a testament to our dedication to quality and precision with every Custom parts manufacturing we produce. Whether you’re looking for prototypes or volume production, you can trust that we have the tools and expertise to deliver the highest quality products based on your specific needs. Contact us today to learn more about how we can help you realize your project with confidence!

Post time: Dec-07-2024