Exciting news from HY Metals! As our business continues to grow, we are thrilled to announce that we have taken a significant step towards enhancing our manufacturing capabilities. Recognizing the increasing demand for our products and the need to further elevate our lead time, quality, and service, we have made a strategic decision to invest in the expansion of our machining infrastructure.

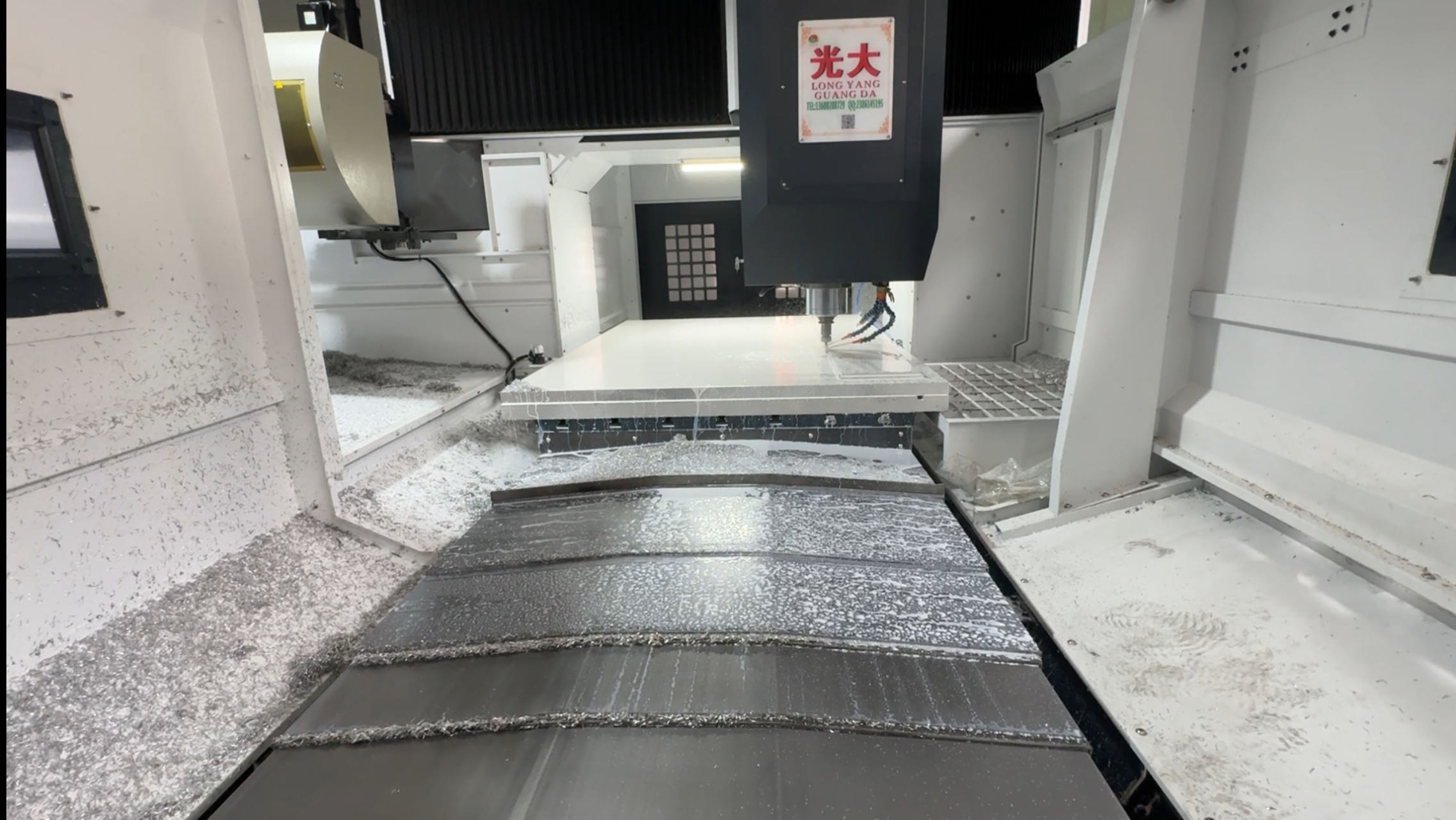

In response to this imperative, HY Metals has recently integrated an impressive array of 25 state-of-the-art precision 5 Axis CNC machines into our production facilities. This substantial addition not only signifies our commitment to meeting the escalating orders from our valued customers but also underscores our unwavering dedication to delivering superior quality and service.

By bolstering our machining capacity, we are poised to significantly streamline our production processes, optimize efficiency, and elevate the precision and accuracy of our components. This investment aligns with our unwavering pursuit of excellence and positions us to better serve our clients with shorter lead times and uncompromising quality.

At HY Metals, we are continuously striving to stay ahead of the curve and remain at the forefront of technological advancements in the industry. This expansion represents a pivotal milestone in our journey, and we are confident that it will empower us to exceed the expectations of our customers while fortifying our position as a leader in the manufacturing sector.

We are incredibly excited about the possibilities that this expansion unlocks and are eager to leverage these new capabilities to drive innovation, elevate our standards, and ultimately, deliver unparalleled value to our clients. Thank you for your continued support as we embark on this exciting new chapter in our growth story.

In today’s rapidly evolving manufacturing industry, precision and efficiency are critical. As technology continues to advance, companies continue to seek innovative solutions to streamline production processes and provide customers with high-quality custom parts. One of the companies leading this revolution is HY Metals, which recently added 25 state-of-the-art CNC milling machines, one of which is capable of processing parts up to 2000mm*1400mm in size.

The integration of advanced CNC machining technology puts HY Metals at the forefront of custom manufacturing, allowing them to deliver unparalleled precision and efficiency in the production process. Capable of performing a variety of operations such as milling, turning and precision machining, these cutting-edge machines significantly expand the company’s capabilities to meet the diverse needs of customers across various industries.

One of the main advantages of CNC machining is its ability to deliver consistent and precise results with minimal human intervention. By utilizing computer-aided design (CAD) and computer-aided manufacturing (CAM) software, HY Metals can program these machines to perform complex operations with unparalleled precision, ensuring that each part meets the exact specifications proposed by the customer. This level of precision not only improves the overall quality of manufactured parts, it also reduces the margin of error, ultimately increasing customer satisfaction.

Furthermore, the addition of a 5-axis CNC mill opens up new areas of possibilities for HY Metals. Unlike traditional 3-axis machine tools, 5-axis machining provides the flexibility to produce complex and multi-dimensional parts with unparalleled efficiency. This feature is especially valuable for industries such as aerospace, automotive, and medical, where complex geometries and tight tolerances are often the norm. With the ability to maneuver cutting tools along five different axes, HY Metals can handle even the most challenging machining tasks with ease, pushing the limits of custom manufacturing.

In addition to technical advantages, investment in advanced CNC machining technology also brings tangible benefits to HY Metals’ customers. The enhanced capabilities of these machines result in faster lead times, meaning customers can achieve faster order turnaround times without compromising on quality. Not only does this speed up the overall production process, it also enables customers to meet project deadlines more efficiently and build a stronger, more reliable partnership with HY Metals.

As the manufacturing landscape continues to evolve, the integration of advanced CNC machining technology is proving to be a game-changer for companies like HY Metals. By embracing innovation and investing in cutting-edge equipment, they are not only improving their capabilities but setting new standards for custom manufacturing. With a focus on precision, efficiency and customer satisfaction, HY Metals is poised to lead industry change, meticulously machining one part at a time.

Post time: Apr-10-2024