In today's manufacturing industry, CNC turning, CNC machining, CNC milling, grinding and other advanced machining techniques are used to create custom metal parts with tight tolerances. The process of creating high-precision machined parts requires a combination of technical knowledge, skill and expertise.

The first step in creating a high-precision machined part is to carefully review the design specifications. Design specifications shall include detailed measurements, tolerances and material requirements. CNC programmers should carefully review design specifications to ensure the CNC machine is set up correctly and the correct tools are used.

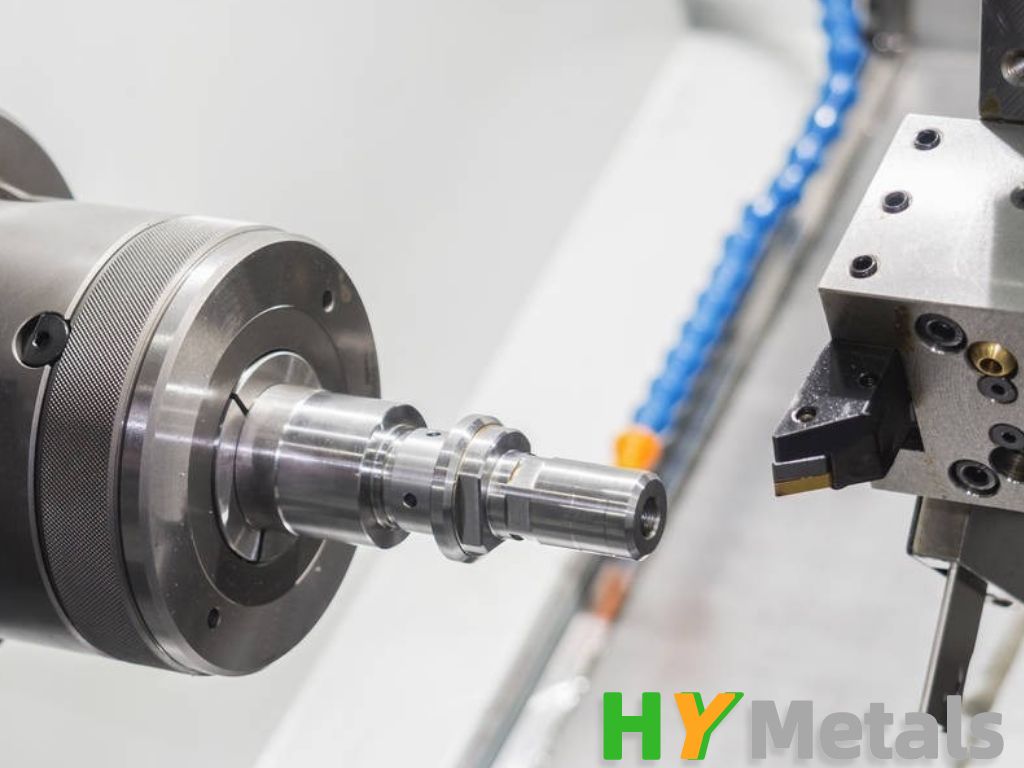

The next step is CNC turning. CNC turning is the process of turning a metal workpiece using a computer-controlled machine and removing material from the surface using cutting tools. This process is used to create cylindrical or circular parts such as shafts or bolts.

Once the CNC turning process is complete, the machinist moves on to CNC milling. CNC milling involves the use of computer-controlled machines to remove material from a block of metal to create custom parts. This process is used to create complex parts with complex shapes or designs.

During CNC turning and milling, machinists must carefully monitor cutting tools to ensure they remain sharp and precise. Blunt or worn tools can cause errors in the final product, causing parts to fall out of tolerance.

Grinding is another important step in the high-precision machining process. Grinding is used to remove small amounts of material from the surface of a part, creating a smooth surface and ensuring the part meets required tolerances. Grinding can be done by hand or using a variety of automated machines.

Tight tolerances are one of the most critical factors in the manufacture of high-precision machined parts. Tight tolerances mean that parts must be manufactured to exact dimensions, and any deviation from that dimension can cause the part to fail. To meet tight tolerances, machinists must carefully monitor the entire machining process and adjust machines as needed.

Finally, custom metal parts must be thoroughly inspected to ensure they meet the required specifications. This may involve the use of specialized measuring equipment or visual inspection. Any deficiencies or deviations from design specifications must be resolved before a part can be considered complete.

In summary, manufacturing high-precision machined parts requires technical expertise, the use of advanced machining techniques, and a commitment to quality control. By following these steps and paying close attention to detail, fabricators can produce custom metal parts that meet the tightest tolerances and highest quality standards.

Post time: Mar-18-2023