HY Metals Expands Precision Manufacturing Capabilities with New Custom Turned Parts & Medical Components

HY Metals Expands Precision Manufacturing Capabilities with New Custom Turned Parts & Medical Components

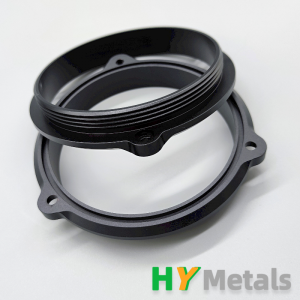

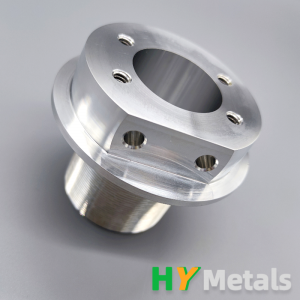

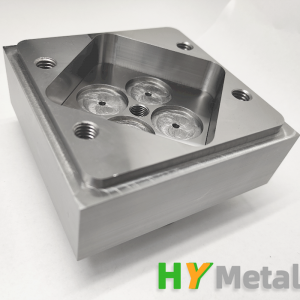

At HY Metals, we’re excited to showcase our latest batch of custom turned parts and medical-grade components – from ultra-precision micro-machined parts (Ø3-4mm x 3mm) to large shafts (Ø500mm x 1000mm). This diverse production run demonstrates our unmatched flexibility in serving industries from medical devices to industrial machinery.

Why These New Components Matter

1. Micro-Precision Expertise

– Delicate medical instrument pins (Ø3mm±0.005mm)

– Threaded micro-fasteners for optical devices

– Surface finish: Ra 0.2μm (mirror polishing available)

2. Large-Dimension Capability

– Long hydraulic cylinders (1000mm length, ±0.02mm straightness)

– Rotary union shafts with precision ground surfaces

3. Medical-Grade Perfection

– Biocompatible titanium bone screw prototypes

– Stainless steel surgical tool components (ISO 13485 compliant)

HY Metals’ Manufacturing Powerhouse

With our 300+ advanced machines across 9 specialized factories, we handle:

✅ Prototypes to Mass Production

– 100+ new part numbers daily

– Batch sizes from 1pc to 50,000+

✅ Uncompromising Quality

– In-process CMM inspection for critical dimensions

– Material certificates (MTC) with full traceability

✅ Industry-Specific Solutions

– Medical: Electropolished, cleanroom-packaged parts

– Automotive: Hard-turned bearing surfaces

– Aerospace: Lightweight aluminum alloys

Our Technical Differentiators

✔ Swiss-type CNC lathes for micro-part accuracy

✔ Multi-axis turning centers for complex geometries

✔ In-house grinding for superior surface finishes

✔ Automated sorting/packaging to prevent handling damage

Recent Client Success:

A UK medical startup reduced their prototype lead time from 5 weeks to 9 days by leveraging our:

- Dedicated quick-turn machining cells

- Concurrent engineering support

- Express shipping options

Partner with a Manufacturing Leader

Whether you need:

- Micro-machined prototypes

- Production-ready turned parts

- Special medical components

HY Metals delivers: