HY Metals Delivers High Precision CNC Turned Part in Record Time

Precision Perfected: HY Metals Delivers Complex CNC Turned Part in Record Time

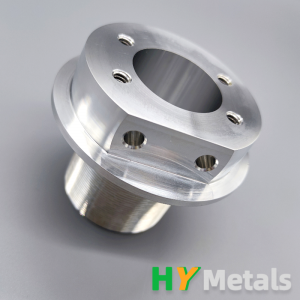

We are excited to showcase our latest CNC turned component – a meticulously engineered AL6061-T6 precision part (Ø30mm×25mm) featuring multiple tapped holes including NPS 1/4-18 threads. This 200-piece order was completed in just 9 days from order to final inspection, demonstrating HY Metals’ commitment to rapid turnaround without compromising quality.

Project Specifications & Challenges

- Material: AL6061-T6 (excellent strength-to-weight ratio)

- Critical Features:

– Multiple through-holes with tight positional tolerances

– NPS 1/4-18 threaded holes requiring precise tap drilling

– Burr-free edges for immediate assembly readiness

- Quantity: 200 pcs (small-batch production)

- Timeline: 9 days from order to shipped quality

Why This Matters for Precision Manufacturing

1. Micro-Tolerance Achievement

– Thread concentricity within ±0.01mm

– Surface roughness Ra 0.8μm (mirror-quality finish)

– Dimensional consistency across all 200 parts

2. Rapid Small-Batch Production

– No minimum order quantity constraints

– 30% faster production than industry standard

– Same-day quoting for turned parts

3. Secondary Processing Excellence

– Deburring: Mechanical tumbling for edge perfection

– Cleaning: Ultrasonic bath treatment

– Packaging: Anti-scratch individual compartments

HY Metals’ CNC Turning Advantages

✅ 15+ Swiss-type CNC Lathes (0.001mm precision)

✅ Live Tooling Capabilities (milling/tapping in one setup)

✅ In-house Thread Gauging (100% thread verification)

✅ Material Certification (full traceability)

Client Benefits Realized

- 9-day complete production cycle (vs. industry average 3 weeks)

- Zero defect rate in first-article inspection

- Cost savings of 25% through optimized machining strategies

- DFM recommendations that improved part durability

Our Technical Differentiation

✔ Smart Factory Integration

– Real-time production monitoring

– Automated tool wear compensation

– Cloud-based progress updates

✔ Quality Assurance Protocol

– First-article CMM verification

– Statistical process control charts

– Final inspection reports included

Industries Served

- Robotics: Joint components & actuator parts

- Medical: Instrumentation housings

- Aerospace: Lightweight structural elements

- Automotive: Sensor mounts & fittings

Your Turned Part Solution Awaits

Whether you require:

- Prototype quantities (1-50 pcs)

- Bridge production (50-1,000 pcs)

- High-volume manufacturing (10,000+ pcs)

HY Metals delivers: