HY Metals Delivers Flawless Sheet Metal Enclosure Prototypes for Equipment Testing

HY Metals Delivers Flawless Sheet Metal Enclosure Prototypes for Equipment Testing

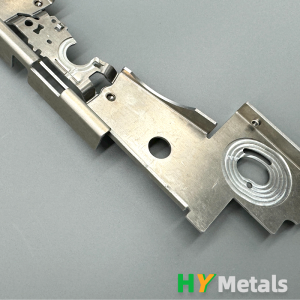

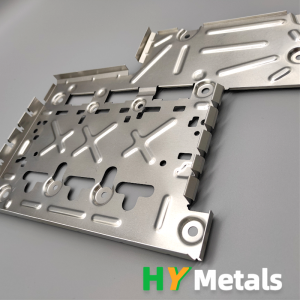

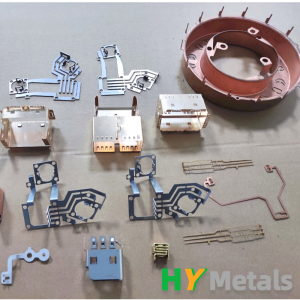

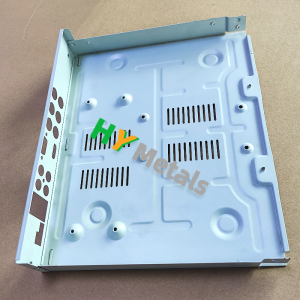

We’re excited to showcase our latest sheet metal enclosure prototype – a precision-crafted 625×450×200mm galvanized steel chassis produced for functional testing. This project demonstrates HY Metals’ expertise in delivering small-batch, high-quality sheet metal fabrication for equipment manufacturers.

Project Highlights

✔ Material: Premium galvanized steel (anti-corrosion treatment)

✔ Quantity: 2 prototype units for field testing

✔ Key Processes:

– Laser cutting (±0.1mm accuracy)

– Precision bending (±0.2° angle tolerance)

– Riveting assembly (flush fastener installation)

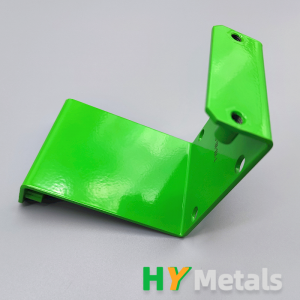

✔ Surface Quality: Scratch-free protective film coating

Why This Matters for Your Projects

1. Prototype-Perfect Results

– First-article inspection confirmed 100% dimensional compliance

– Burr-free edges ready for immediate installation

– Perfect flatness (<0.3mm/m² deviation)

2. Small-Batch Specialization

– No minimum order quantity for prototypes

– Same quality standards as production runs

– 10-12 day typical lead time for testing samples

3. Testing-Ready Fabrication

– Pre-installed mounting points

– EMI shielding preparation

– Custom labeling options available

Our Sheet Metal Prototyping Edge

✅ Dedicated Quick-Turn Prototype Line

✅ 3D File to Finished Product in 2 Weeks

✅ Engineering Support for DFM Optimization

Recent Client Success:

An industrial sensor manufacturer reduced their enclosure development time by 40% using our:

- Rapid prototyping capabilities

- Material thickness recommendations

- Assembly simplification advice

Get Your Custom Enclosure Quote Today

Whether you need:

- Equipment housing prototypes

- Small-batch test units

- Production-ready designs

HY Metals delivers: