Hot sale Prototype Machined Parts - Urethane casting for rapid prototypes and low volume production – HY Metals

Hot sale Prototype Machined Parts - Urethane casting for rapid prototypes and low volume production – HY Metals Detail:

What is Urethane casting or called as Vaccum casting?

Urethane casting or Vaccum casting is a very commonly used and well-developed rapid tooling process with rubber or silicone molds to produce high-quality prototype or production parts in around 1-2 weeks. Compared with metal injection molds it is much faster and much cheaper.

Urethane casting is much more suitable for the prototypes and the low-volume production than the expensive injection molds. We all know the injection molds are quite complex,expensive,and takes weeks even months to finish. But for some prototype projects, you may have no so much time and money to budget. Urethane casting will be a great alternative solution.

How Urethane casting make parts?

Urethane casting is a rapid molding and copy process.

Step1. Prototyping

According to the 3D drawings supplied by the customer, HY Metals will make a highly accurate master pattern with 3D printing or CNC machining.

Step2. Make the silicone mold

After the prototype pattern is made, HY Metals will build a box around the pattern and add gates, sprues, parting lines to the pattern. Then the liquid silicone is poured around the pattern. After 8 hours of drying, remove the prototype, and the silicone mold is manufactured.

Step3.Vaccum Casting parts

The mold is then ready to be filled with urethane, silicone, or another plastic material(ABS、PC、PP、PA). The liquid material was injected into the silicone mold under pressure or vacuum, after 30-60 min of curing in a 60° -70° incubator ,parts can be removed from the mold which will be perfectly match the original pattern.

Generally, the service life of silicone mold is around 17-20 times.

So if the QTY of your order is 40 or more,we just need to make 2 sets or more same mold.

Why and when choose Urethane casting to make parts?

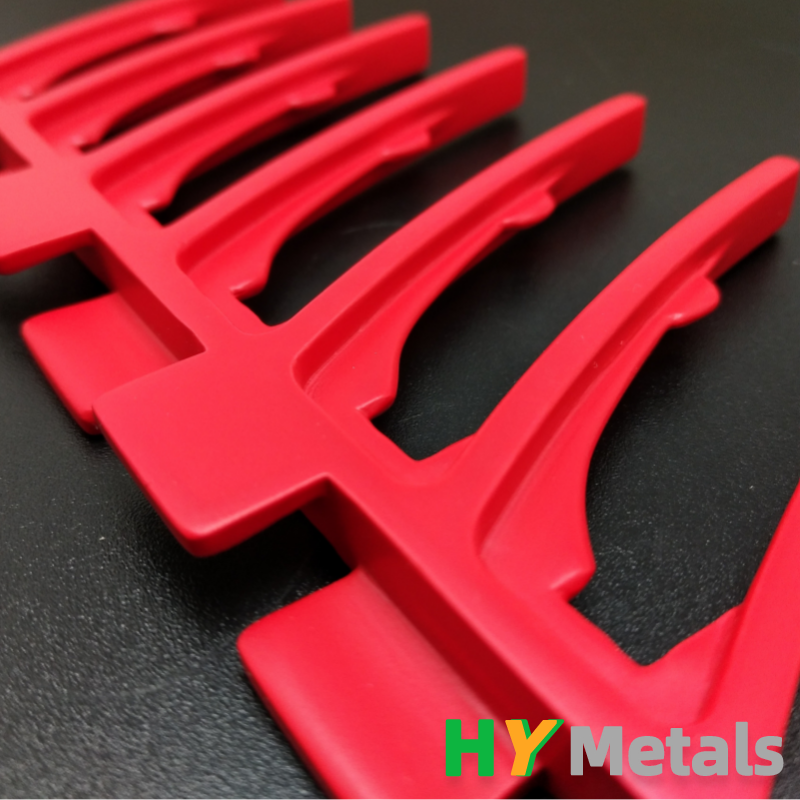

The cast urethane process offers an extremely wide range of material, color, and texture options. Urethane cast parts can also be clear, color-matched, painted, have installed inserts, and custom-finished.

Advantage of Urethane Casting:

The cast urethane process offers an extremely wide range of material, color, and texture options. Urethane cast parts can also be clear, color-matched, painted, have installed inserts, and custom-finished.

● Tooling cost is lower

● Delivery is very fast

● Cost-effective for prototype and low-volume production

● High temperature resistance

● Mold can be used repeatedly 20 times

● Flexible for design changes

● Available for highly complex or tiny parts

● Overmolded features with different materials, multiple durometers and colors

When you have a plastic parts designed complex and meet above specifications ,and need a small scale order like 10-100 sets, you don’t want to make injection tooling and need parts urgently, then you can choose HY Metals for Urethane casting or vaccum casting.

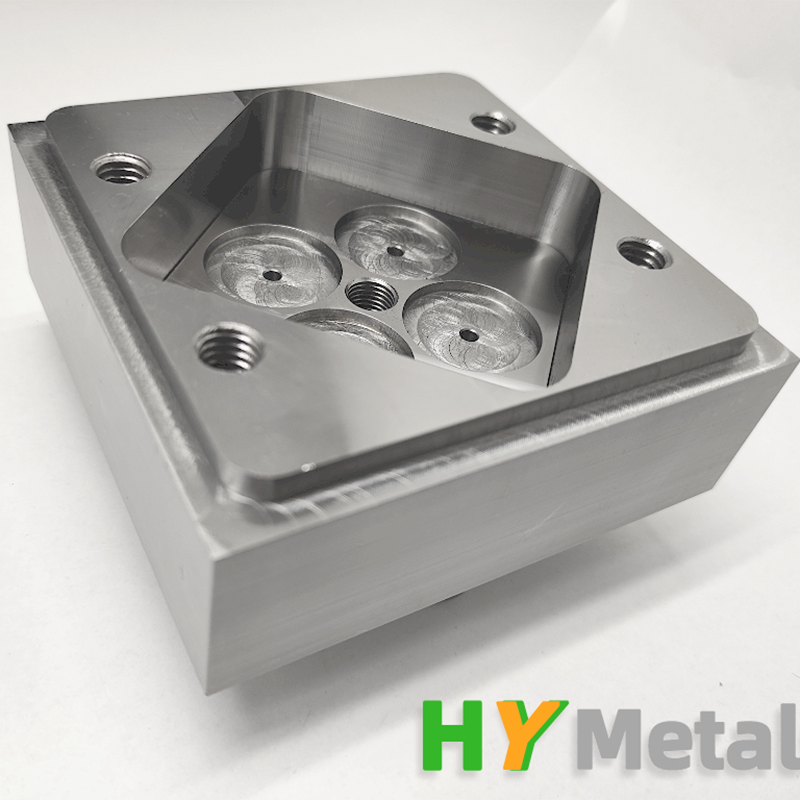

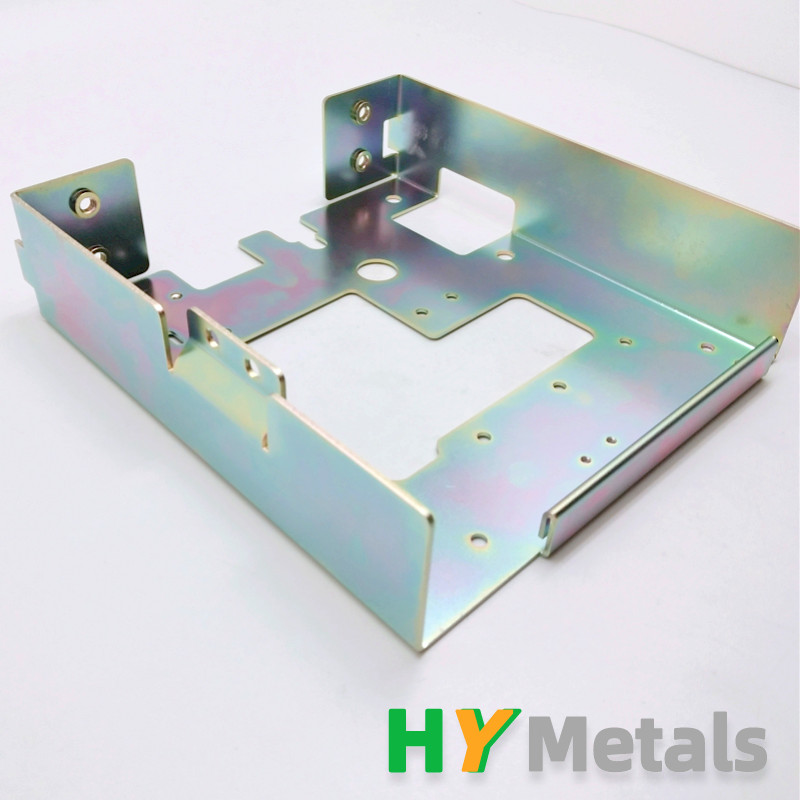

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Hot sale Prototype Machined Parts - Urethane casting for rapid prototypes and low volume production – HY Metals , The product will supply to all over the world, such as: Slovakia, Berlin, Denver, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.