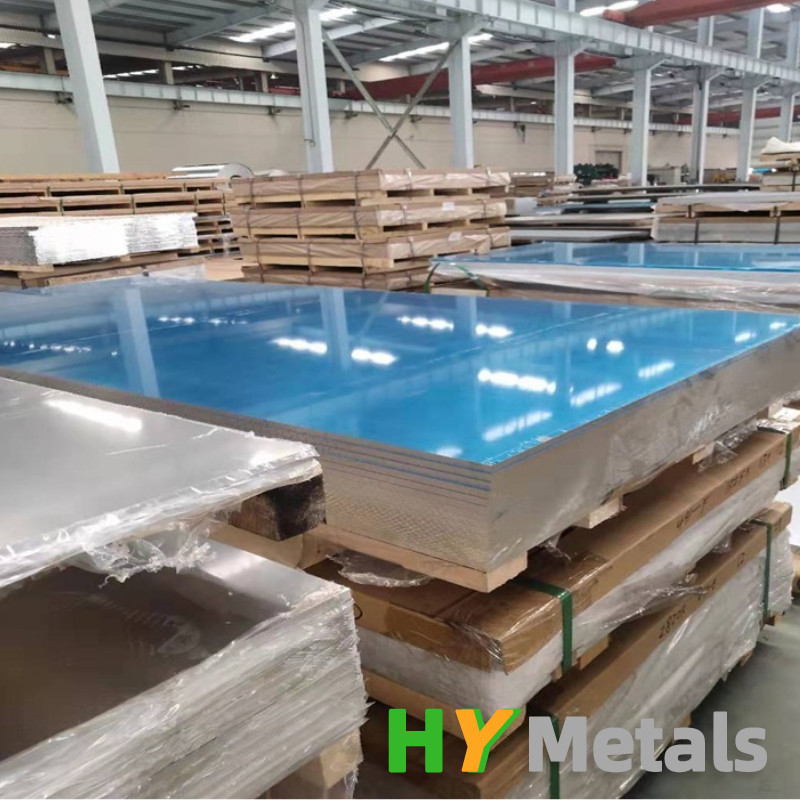

Good quality Sheet Metal Components - Custom sheet metal welding and assembly – HY Metals

Good quality Sheet Metal Components - Custom sheet metal welding and assembly – HY Metals Detail:

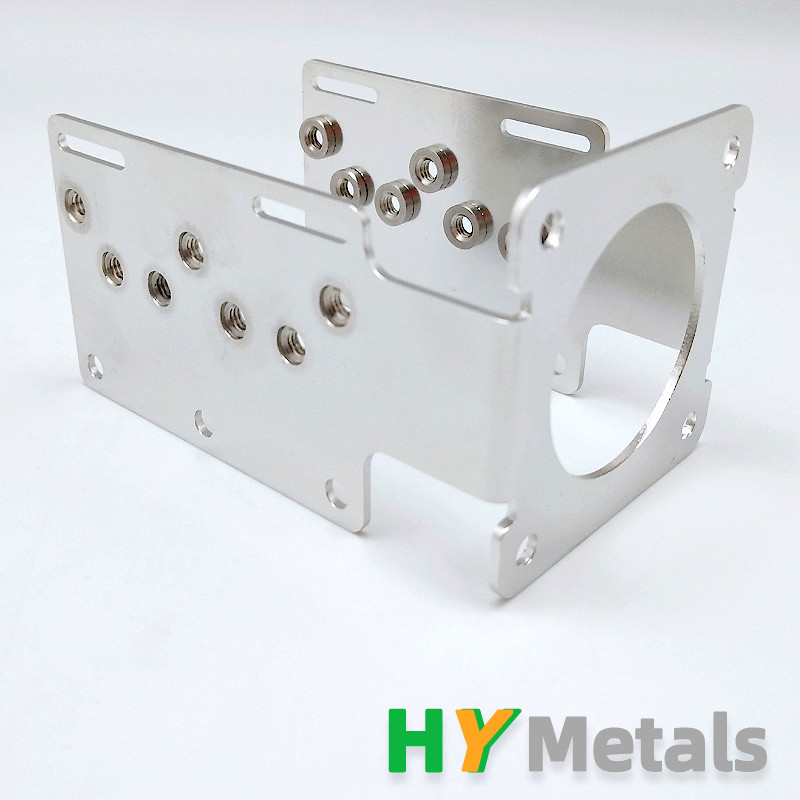

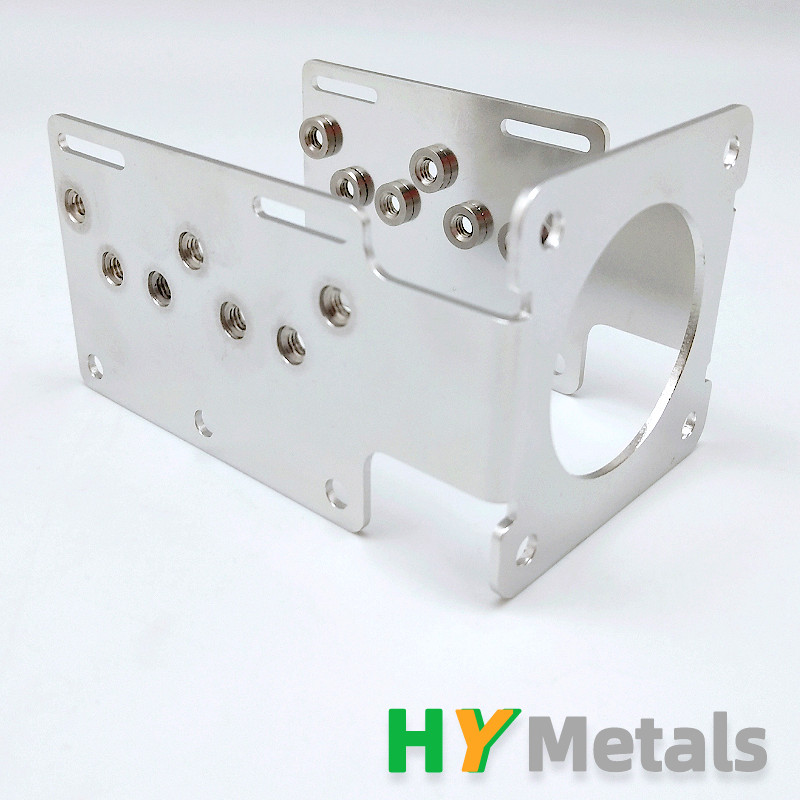

Sheet Metal Fabrication Processes: Cutting, Bending or Forming, Tapping or Riveting, Welding and Assembly.

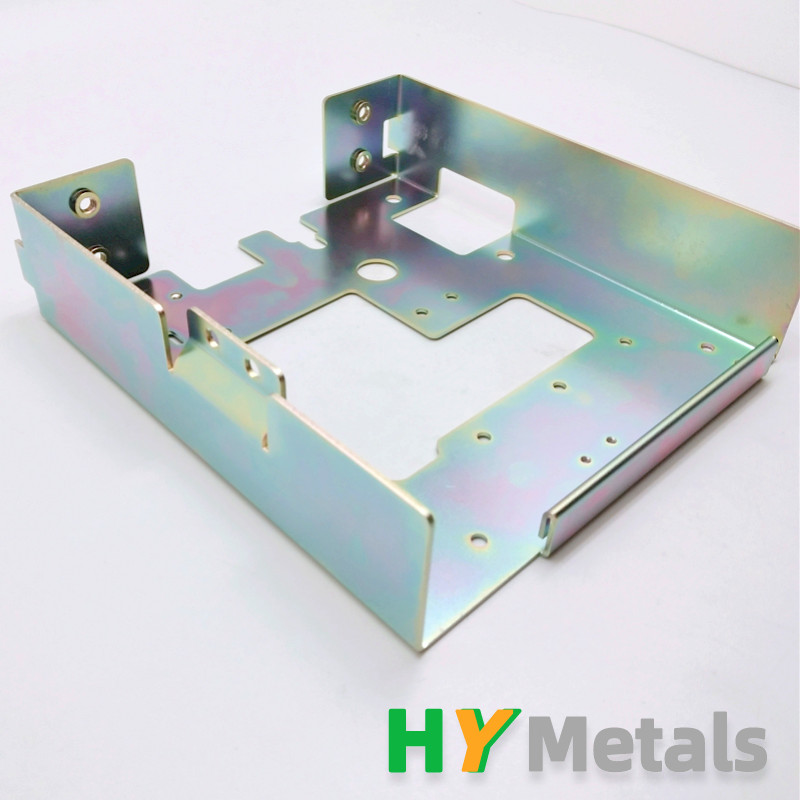

Sheet metal assembly is the process after cutting and bending, sometimes it is after coating process. We usually assemble parts by riveting, welding, pressing fit and tapping to screw them together.

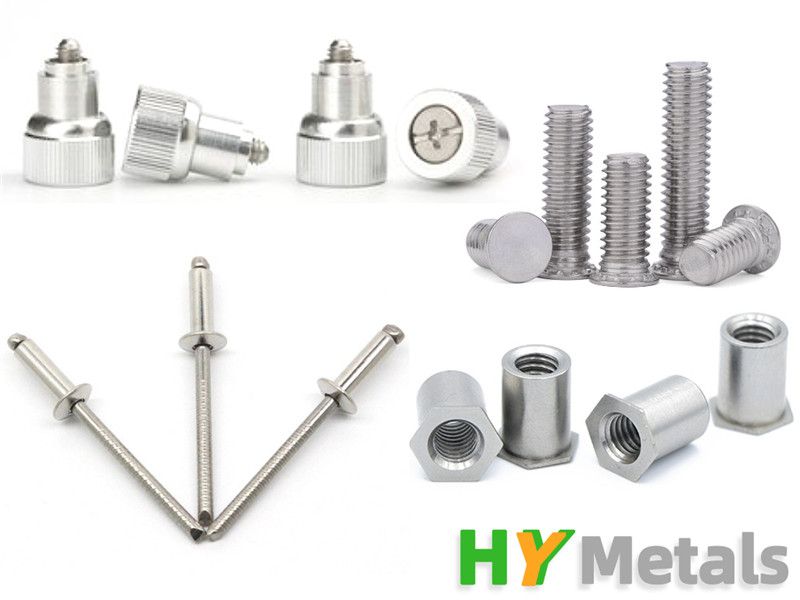

Tapping and Riveting

Threads are playing an important role in assemblies. There are 3 main methods to get threads: Tapping, riveting, install coils.

1. Tapping threads

Tapping is a process making threads in the holes for sheet metal parts or CNC machined parts with tap machine and tap tools. It is widely used on some thick and hard material such as steel and stainless steel parts.

For thin metal or soft materials like aluminum and plastic parts, riveting and install coils will work better.

2. Riveting Nuts and Standoffs

Riveting is the simplest and most commonly used assembly method in sheet metal processing.

Riveting can provide longer and stronger threads than tapping for thin metal plate

There are a lot of Nuts, screws and standoffs for riveting. You can get all standard size PEM hardware and some MacMaster-Carr hardware from HY Metals for your assembly.

For some special hardware we can’t source in local shops, you can provide to us for assembling.

3. Installing Heli-coil insert

For some thick but soft materials like plastic machined parts, we usually install Heli-coil inserts into the machined holes to get threads for assembly.

Press Fit

Press fitting is suitable for some pins and shaft assembly, and widely used in machined parts, sometimes needed in sheet metal projects.

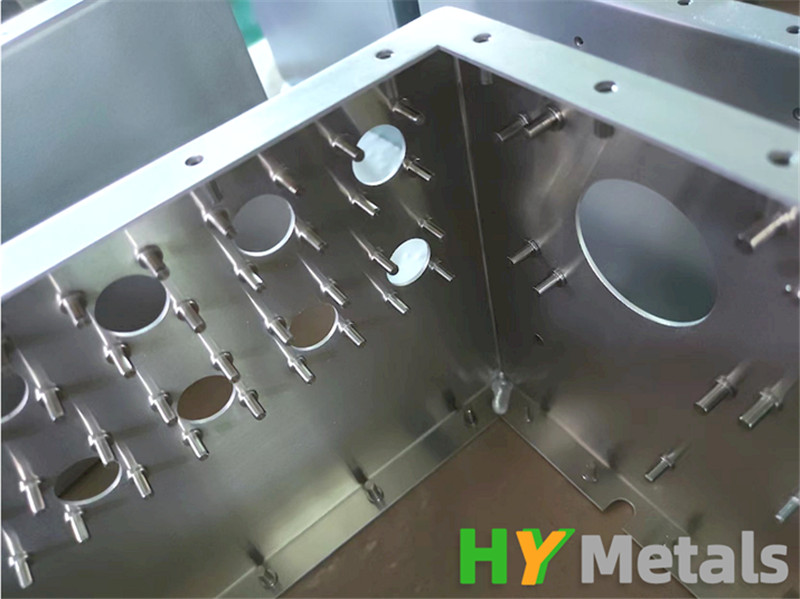

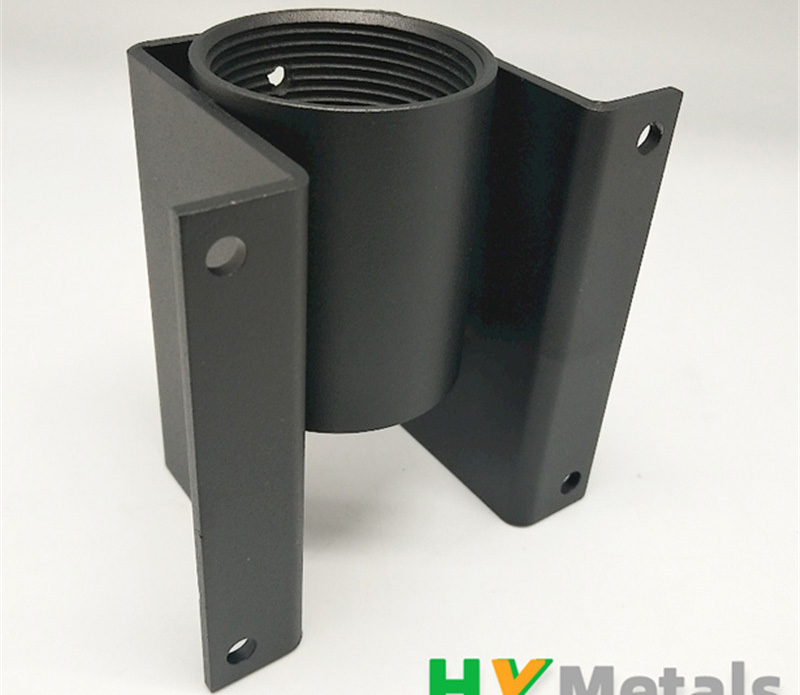

Welding

Welding is another commonly used assembly method in sheet metal fabrication. Welding can make several parts joint together strongly.

HY Metals can do laser welding, Argon-arc welding and Carbon dioxide arc welding.

According to the metal welding works level, it is divided into spot welding, full welding, water proof welding.

We can meet all your requirement on metal welding for your assemblies.

Sometimes, we will polish the welding marks to get a smooth surface before coating.

Product detail pictures:

Related Product Guide:

We're going to commit ourselves to giving our esteemed buyers using enthusiastically considerate solutions for Good quality Sheet Metal Components - Custom sheet metal welding and assembly – HY Metals , The product will supply to all over the world, such as: Nicaragua, South Africa, London, Taking the core concept of to be the Responsible. We'll redound up on society for high quality merchandise and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.