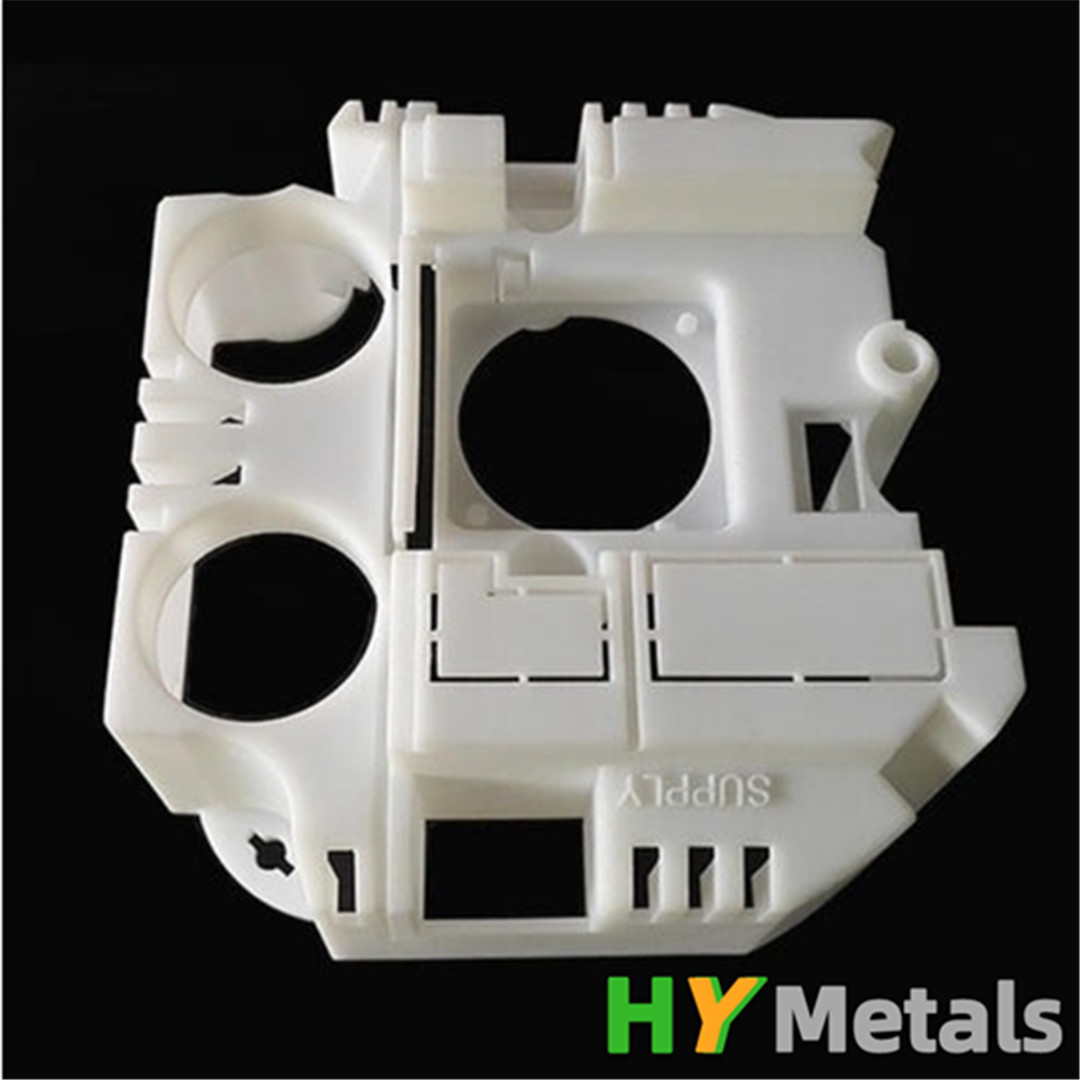

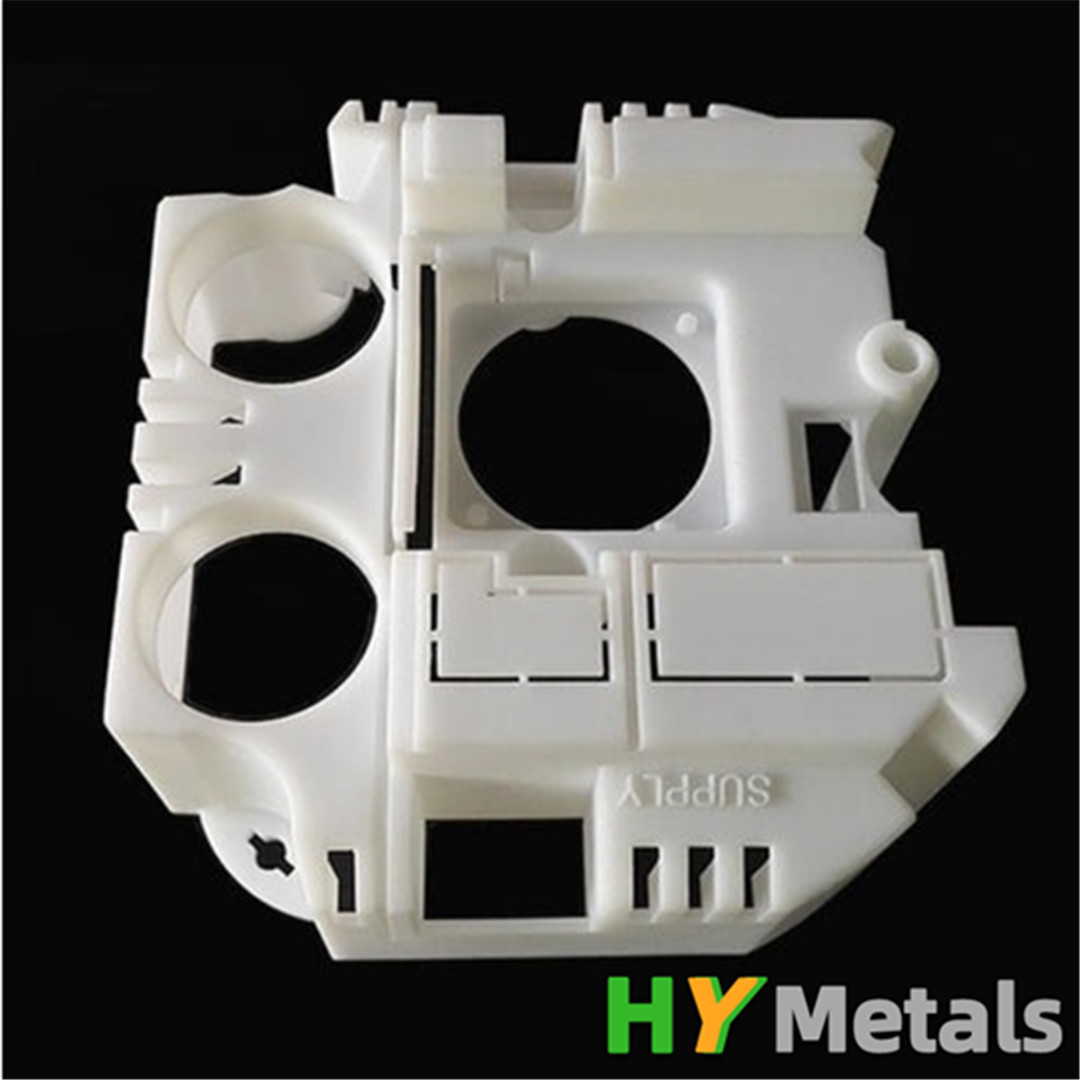

Chinese wholesale Prototyping Models - 3D printing service for rapid prototype parts – HY Metals

Chinese wholesale Prototyping Models - 3D printing service for rapid prototype parts – HY Metals Detail:

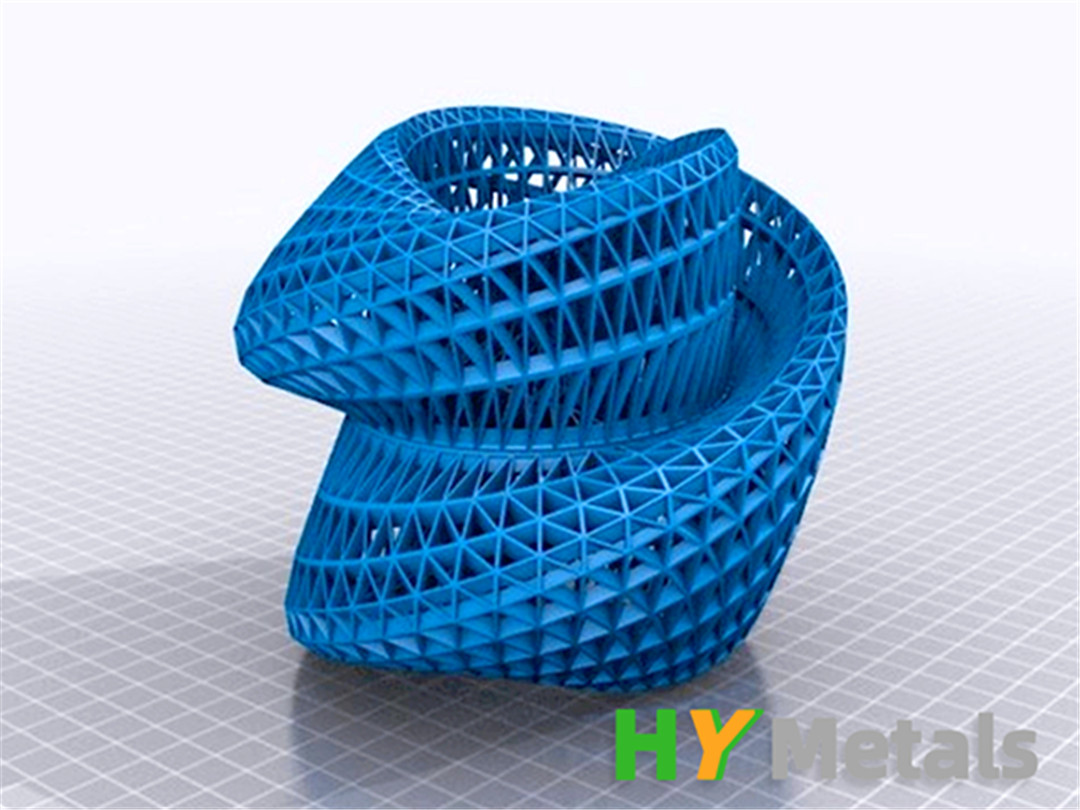

The Advantages of 3D printing?

● Very fast delivery,2-3 days possible

● Much more cheaper than traditional process.

● 3D Printing technology break through the traditional manufacturing technology. Everything is possible to be printed.

● Overall printing, no assembly, save time and labors.

● Product diversification does not increase costs.

● Reduced reliance on artificial skills.

● Material infinite combination.

● There is no waste of tail material.

The common 3D printing techniques:

1. FDM: Melt deposition molding, the main material is ABS

2. SLA: Light curing rotten molding, the main material is photosensitive resin

3. DLP: Digital light processing molding, the main material is photosensitive resin

The forming principle of SLA and DLP technology is the same. SLA technology adopts laser polarization scanning irradiation point curing, and DLP adopts digital projection technology for layered curing. The accuracy and printing speed of DLP are better than SLA classification.

What types of 3D printing can HY Metals handle?

FDM and SLA are the most used in HY Metals.

And the most commonly used materials are ABS and photosensitive resin.

3D printing is much cheaper and faster than CNC machining or vaccum casting when the QTY is low like 1-10 sets, especially for complex structures.

However, it is limited by the printed material. We can only printed some plastic parts and very limit metal parts so for. And also, the surface of the printed parts are not as smooth as machining parts.

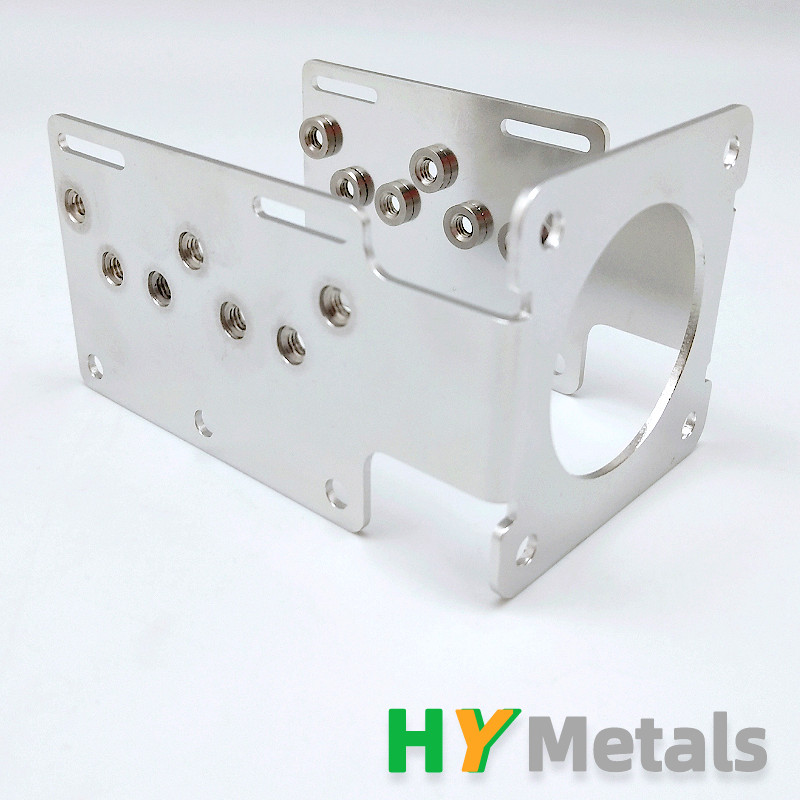

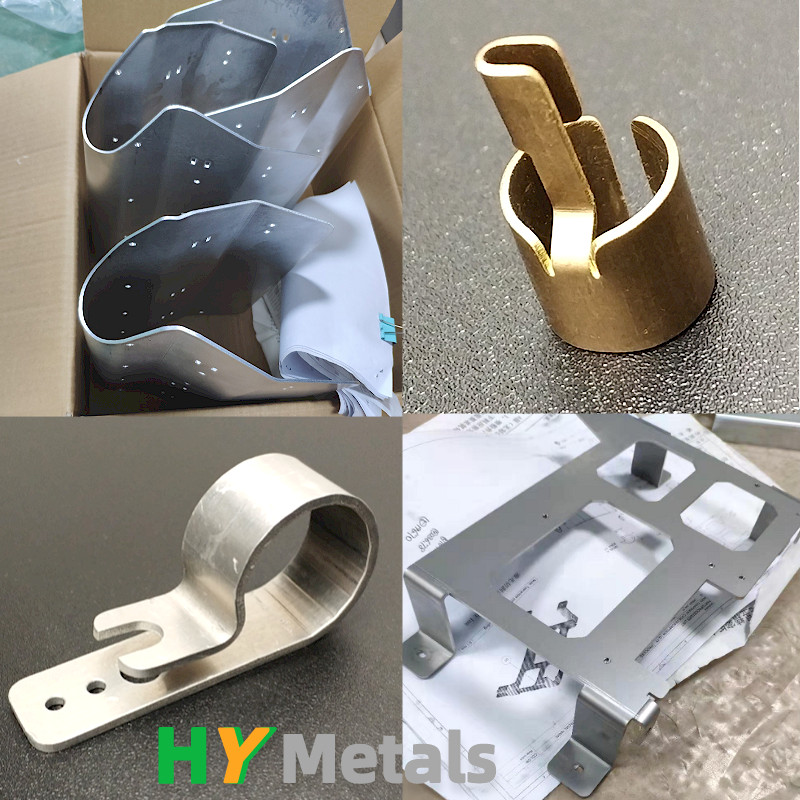

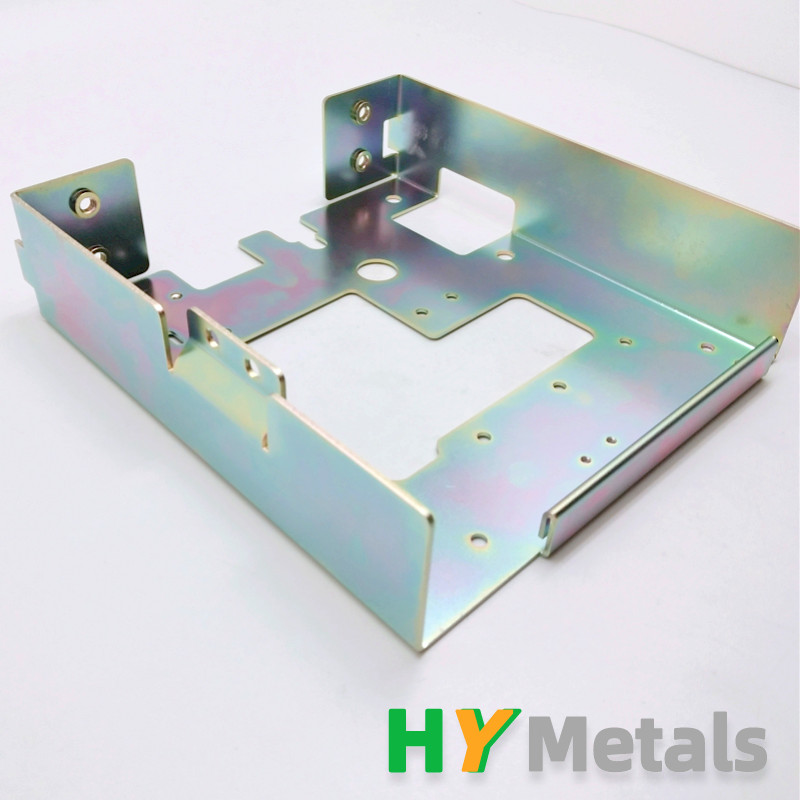

Product detail pictures:

Related Product Guide:

We can easily normally satisfy our respected buyers with our excellent high-quality, excellent selling price and good service due to we've been far more expert and more hard-working and do it in cost-effective way for Chinese wholesale Prototyping Models - 3D printing service for rapid prototype parts – HY Metals , The product will supply to all over the world, such as: Hyderabad, Morocco, Haiti, We are increasingly expanding our international market share based on quality products, excellent service, reasonable price and timely delivery. Please contact us at any time for more information.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.