Revolutionizing Robotics Manufacturing: HY Metals Delivers Precision CNC-Machined Robotic Arm Bracket

The global robotics industry is experiencing unprecedented growth, with AI-powered automation transforming factories, warehouses, and laboratories worldwide.

At HY Metals, we’ve witnessed this boom firsthand, having successfully delivered precision CNC-machined components for over 50 robotics startups and established manufacturers in the past two years alone.

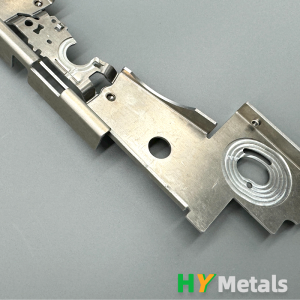

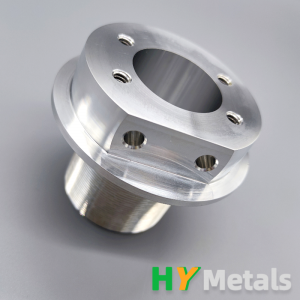

At HY Metals, we’re proud to introduce our latest CNC-machined robotic arm connector – a high-precision AL6061-T6 arm bracket (405mm length) engineered for next-generation automation systems. This complex component showcases our growing expertise in serving the booming robotics industry with mission-critical parts.

Why Robotics Manufacturers Choose HY Metals

1. Precision That Powers Movement

Our newly launched robotic arm bracket demonstrates:

✔ ±0.02mm positional accuracy for flawless articulation

✔ 5-axis CNC milling for complex contouring

✔ Stress-relieved T6 temper for vibration resistance

2. Full-Spectrum Robotics Support

We’ve helped 50+ robotics companies with:

✅ Prototype development (3-5 day quick-turn)

✅ Small-batch testing (10-100pcs)

✅ Production scaling (1,000+ units monthly)

3. Materials Mastery

- Aluminum 6061/7075: Lightweight structural components

- Stainless Steel 303/304: Wear-resistant joints

- Titanium Grade 5: High-strength actuators

Our Robotics Manufacturing Edge

A. Engineering Partnership Approach

- Free DFM feedback to optimize part performance

- Tolerance analysis for moving assemblies

- Surface treatment recommendations (anodizing, nickel plating)

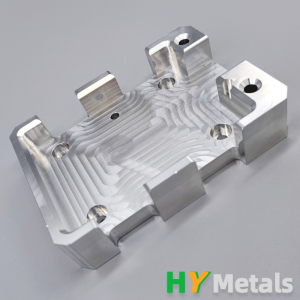

B. Advanced Production Capabilities

- 15+ CNC milling centers with 4th/5th axis capability

- In-house CMM verification for critical dimensions

- Custom fixturing solutions for complex geometries

C. Accelerated Development Cycles

- 70% faster prototyping vs. traditional machine shops

- Concurrent engineering support during testing phases

- Inventory management programs for recurring orders

Success Story: Robotic Gripper Revolution

A Boston-based automation startup reduced their:

- Prototype costs by 40% through our material optimization

- Assembly time by 25% with our precision-tolerance parts

- Time-to-market by 6 weeks using our rapid CNC services

Your Robotics Manufacturing Solution

Whether you need:

- Collaborative robot components

- Industrial robotic structural parts

- Custom end-effector adapters

HY Metals delivers: