In the processing of Precision machining and custom manufacturing design, threads play a vital role in ensuring components fit securely and operate efficiently. Whether you are working with screws, bolts, or other fasteners, it is important to understand the differences between the various threads. In this blog, we will explore the differences between left-hand and right-hand threads, single-lead and double-lead(or Dual-Lead)threads, and provide more insights into thread specifications and applications.

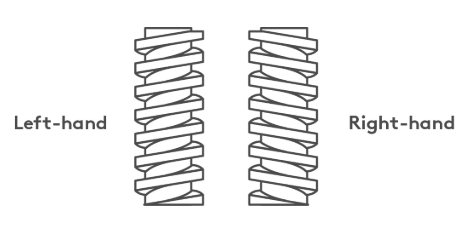

- Right-hand thread and left-hand thread

1.1 Right-hand thread

Right-hand threads are the most common thread type used in machining. They are designed to tighten when turned clockwise and loosen when turned counterclockwise. This is the standard thread convention and most tools, fasteners and components are manufactured with right-hand threads.

Application:

- General purpose screws and bolts

- Most mechanical components

- Everyday items such as jars and bottles

1.2 Left-hand thread

On the other hand, left-hand threads tighten when turned counterclockwise and loosen when turned clockwise. These threads are less common but essential in certain applications where the rotational motion of the component may cause a right-hand thread to loosen.

Application:

- Certain types of bicycle pedals

- Some car parts (e.g. left side wheel nuts)

- Specialized machinery mainly for counterclockwise rotation

1.3 Main Differences

- Direction of rotation: Right-hand threads tighten clockwise; left-hand threads tighten counterclockwise.

- Purpose: Right-hand threads are standard; left-hand threads are used for specialized applications to prevent loosening.

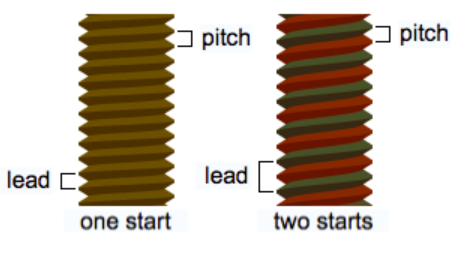

- Single lead thread and double lead thread

2.1 Single lead thread

Single lead threads have one continuous thread that spirals around the shaft. This means that for each revolution of the screw or bolt, it advances linearly a distance equal to the thread pitch.

Feature:

- Simple design and manufacturing

- Suitable for applications requiring precise linear motion

- Commonly used for standard screws and bolts

2.2 Dual lead thread

Dual lead threads have two parallel threads, so they advance more linearly per revolution. For example, if a single lead thread has a pitch of 1 mm, a double lead thread with the same pitch will advance 2 mm per revolution.

Feature:

- Faster assembly and disassembly due to increased linear motion

- Ideal for applications requiring quick adjustments or frequent assembly

- Commonly used in screws, jacks and certain types of fasteners

2.3 Main Differences

- Amount of advance per revolution: Single lead threads advance at their pitch; double lead threads advance at twice their pitch.

- Operation Speed: Dual lead threads allow for faster movement, making it suitable for applications where speed is critical.

- Additional threading knowledge

3.1 Pitch

Pitch is the distance between adjacent threads and is measured in millimeters (metric) or threads per inch (imperial). It is a key factor in determining how tightly a fastener fits and how much load it can withstand.

3.2 Thread Tolerance

Thread tolerance is the permissible deviation of a thread from a specified dimension. In precision applications, tight tolerances are essential, while in less critical situations, looser tolerances are acceptable.

3.3 Thread Form

l There are many thread forms, including:

- Unified Thread Standard (UTS): Common in the United States, used for general-purpose fasteners.

- Metric threads: widely used worldwide and defined by the International Organization for Standardization (ISO).

- Trapezoidal thread: used in power transmission applications, it features a trapezoidal shape for better load-bearing capacity.

3.4 Thread Coating

To improve performance and protect against corrosion, threads can be coated with various materials such as zinc, nickel or other protective coatings. These coatings can increase the life and reliability of threaded connections.

- In conclusion

Understanding the differences between left-hand and right-hand threads and single-lead and double-lead threads is essential for HY Metals workers and our customers involved in machining and manufacturing. By selecting the proper thread type for your application, you can ensure secure connections, efficient assembly, and optimal performance. Whether you are designing a new product or maintaining existing machinery, a solid grasp of thread specifications will greatly benefit your design and machining work.

HY Metals provide one-stop custom manufacturing services including sheet metal fabrication and CNC machining, 14 years experiences and 8 fully owned facilities.

Excellent Quality control, short turnaround, great communication.

Send your RFQ with detailed drawings today. We will quote for you ASAP.

WeChat:na09260838

Tell:+86 15815874097

Email:susanx@hymetalproducts.com

Post time: Dec-11-2024