Precision Sheet Metal Forming and Simplified Tooling Design: A Cost-Effective Solution for Prototypes and Small Batches

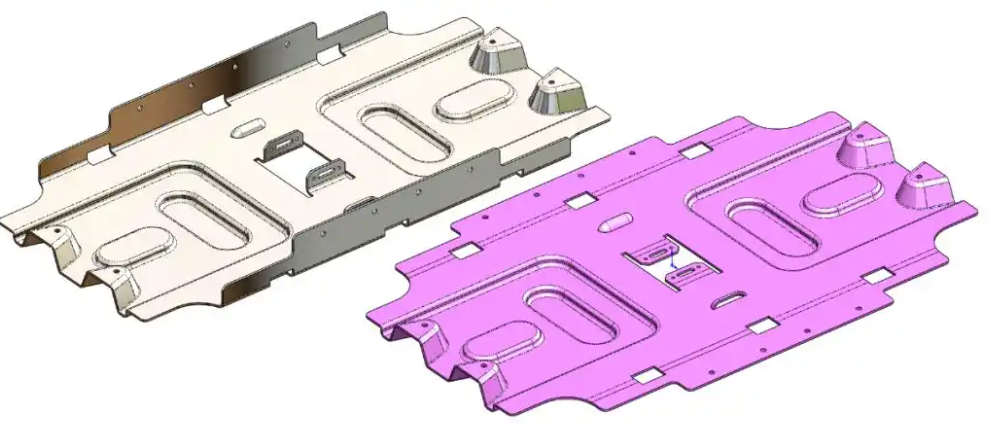

In the realm of sheet metal fabrication, precision forming and tooling design are critical for producing complex components with unique structural features. At HY Metals, we specialize in creating precision sheet metal prototypes and small-batch parts with intricate geometries, such as dimples (凸包), reinforcing ribs (加强筋), and complex curved surfaces commonly found in automotive applications. Our expertise in simplified tooling (short-run tooling or prototype tooling)design allows us to deliver high-quality results while saving clients the cost of expensive formal steel molds.

————————————————————————–

Challenges in Precision Sheet Metal Forming

1. Complex Geometries:

Components with features like dimples or reinforcing ribs require precise control over material flow and deformation. Achieving consistent results without defects such as cracking or wrinkling is a key challenge.

2. Accuracy Control:

Maintaining tight tolerances in precision sheet metal forming is essential, especially for parts with complex curved surfaces. Even minor deviations can affect fit and functionality.

3. Tooling Design:

Simplified tooling must be both cost-effective and functional, balancing ease of production with the ability to achieve the desired form. This requires innovative design and a deep understanding of material behavior.

—————————————————————————-

Key Design Considerations for Simplified Tooling(short-run tooling)

1. Material Selection:

The choice of tooling material depends on the production volume and complexity of the part. For prototypes and small batches, materials like aluminum or resin are often used to reduce costs and lead times.

2. Tooling Form:

Simplified tooling can take various forms, such as modular dies, soft tools, or 3D-printed molds. These tools are designed to be easy to manufacture and adjust, ensuring flexibility for different projects.

3. Precision and Repeatability:

Even with simplified tooling, maintaining precision is crucial. Our engineers use advanced CAD/CAM software to design tools that ensure consistent results across multiple production runs.

————————————————————————–

HY Metals’ Expertise in Simplified Tooling Design

At HY Metals, we have a dedicated team of tooling design engineers and sheet metal design engineers who work closely with clients to develop cost-effective solutions for precision sheet metal forming. Here’s how we excel:

1. Rapid Prototyping:

For sheet metal prototypes, we design and produce simplified tooling that allows for quick iteration and testing. This approach reduces development time and costs, enabling clients to validate designs before committing to formal tooling.

2. Small-Batch Production:

For small-batch orders, our simplified tooling solutions are ideal. They provide the precision and consistency needed for parts with dimples, reinforcing ribs, or complex curved surfaces, without the high cost of steel molds.

3. Custom Solutions:

Every project is unique, and our engineers tailor the tooling design to meet specific requirements. Whether it’s a precision sheet metal component for the automotive industry or a custom prototype for electronics, we deliver solutions that work.

—————————————————————————

Advantages of Simplified Tooling

- Cost Savings: By avoiding the expense of formal steel molds, clients can significantly reduce upfront costs.

- Faster Turnaround: Simplified tooling can be designed and manufactured quickly, enabling shorter lead times.

- Flexibility: Adjustments to the tooling can be made easily, allowing for design changes or improvements during the prototyping phase.

—————————————————————————

Conclusion

Precision sheet metal forming and simplified tooling design are essential for producing high-quality prototypes and small-batch parts with complex geometries. At HY Metals, our team of skilled engineers leverages advanced design tools and innovative approaches to create cost-effective, functional tooling that meets the highest standards of precision and quality.

Whether you need sheet metal prototypes or small-batch production of custom sheet metal parts, HY Metals is your trusted partner. Let us help you bring your designs to life with efficiency, accuracy, and cost savings. Contact us today to learn more about our sheet metal fabrication and tooling design capabilities!

HY Metals provide one-stop custom manufacturing services including sheet metal fabrication and CNC machining, 14 years experiences and 8 fully owned facilities.

Excellent Quality control, short turnaround, great communication.

Send your RFQ with detailed drawings today. We will quote for you ASAP.

WeChat:na09260838

Tell:+86 15815874097

Email:susanx@hymetalproducts.com

Post time: Feb-13-2025